ZTRFM OEM ODM plain square steel gutter downspout roll forming machine

Downpipe use. Collecting roof rainwater is an integral part of the falling water system, which is concentrated into the rainwater pipes laid below the ground. Downpipe material can be divided into: 1. Metal pipes (such as cast iron pipes, colored aluminum pipes, copper pipes, colored steel pipes, etc.) 2. Plastic pipes (such as PVC pipes, etc.)

Profile drawing as below

Here is the downspout profile drawing and dimensions for your reference.

This interlock design don’t need any welding, it can save cost in machine production.

Product | |

Details | Parameter |

Raw material | PPGI,PPGL,GI,GL |

Material thickness | 0.5-0.8 mm |

Cutting length | Adjustable |

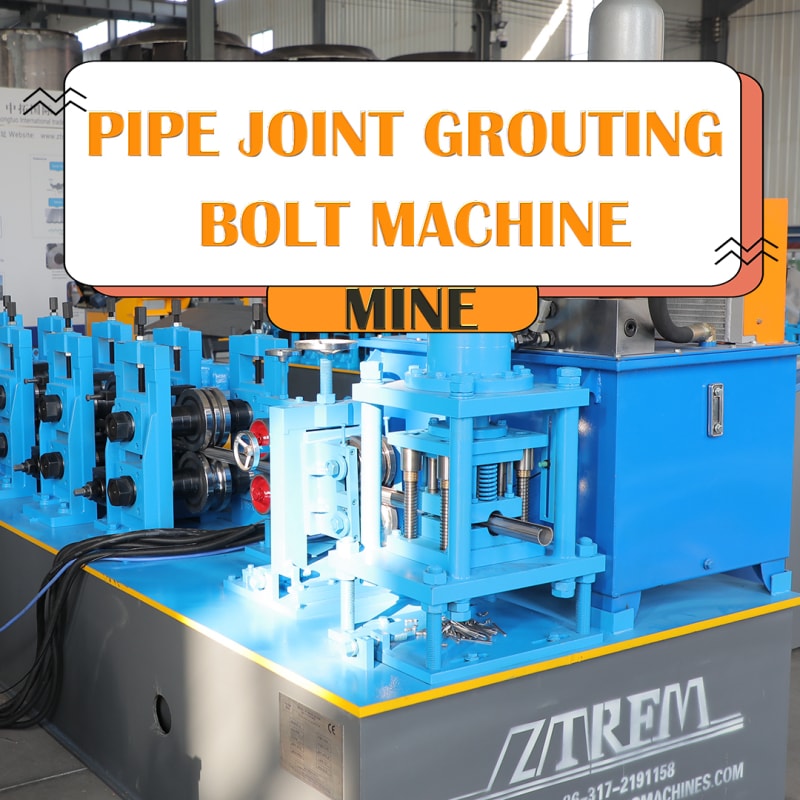

PRODUCT DISPLAY

Decoiler Work type:Passive type Loading capacity:3 Tons Coil inner diameter:450-550 mm (adjustable) Quantity:1 set | |

Roll Forming System Rolling shaft: Shaft material: 45# steel Shaft diameter: 70 mm Tempering treatment Roller: Roller material: 45# steel Chromed treatment, improve the hardness and prevent abrasion, anti corrosion increase of service life Rolling station number:22 stations Work speed:0-10 m/min Machine frame:20mm thick steel wall plate Bearing:Chinese famous brand Harbin Work power:7.5 kw Transmission:By chains | |

PLC Control System Frequency brand: Delta (original) PLC brand: Delta (original) Screen type: Touch screen & buttons Screen language:English/Chinese Encoder: Omron Low pressure electrical part brand: Schneider Function: Cutting length and quantity control, speed adjustment control, dimension adjust. | |

Hydraulic cutting device PLC brand: DELTA brand Work type: hydraulic power cutting the downspout into length Hydraulic power: 3 kw Cutting length tolerance:±1 mm/3 m Cutting feature: Automatic cutting after forming, no distorting. |

Afer-Sale Service

1.Payment: 30%T/T in advance and 70%balance after testing and before shipment.

2.Delivery: 50 working days after the deposit.

3.Validity time: 15 working days

4.After-sales service

A: Warranty: One year ,and we will provide the technical support for the whole life.some spare parts are available.

B: Training and service: the buyer should charge of visa, round-trip ticket, food and accommodation overseas and USD 80/person/day for salary.

C.The advantage of my factory: we have a team of skilled engineers and one group for after-sale service.

D: we will provide you the manual for installation, operation and maintenance in English.