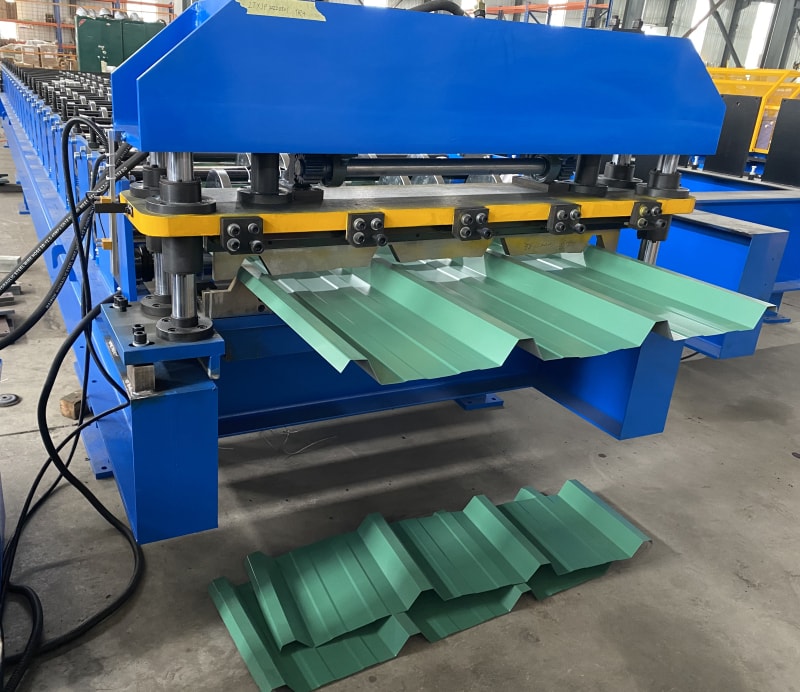

Tile pressing machine is composed of discharging, molding, after molding and cutting to produce the color plate appearance flat and beautiful, uniform paint pattern, high strength, durable, widely used in industrial civil buildings, such as factories, warehouses, gymnasiums, exhibition halls, theaters and other room surfaces and walls.

Tile press its components include: color steel tile press machine machine, PLC computer control system, hydraulic pump station system, automatic after shear system equipment features: the color steel plate equipment using high level automatic control software, color steel tile press machine to achieve the production of information governance.

The whole unit automation control system adopts highly integrated network, which makes the automation system function better.

There are many parameters to be set for the tile pressing machine, which are set with the text screen. There are two kinds of parameter setting: equipment parameter and user parameter setting.

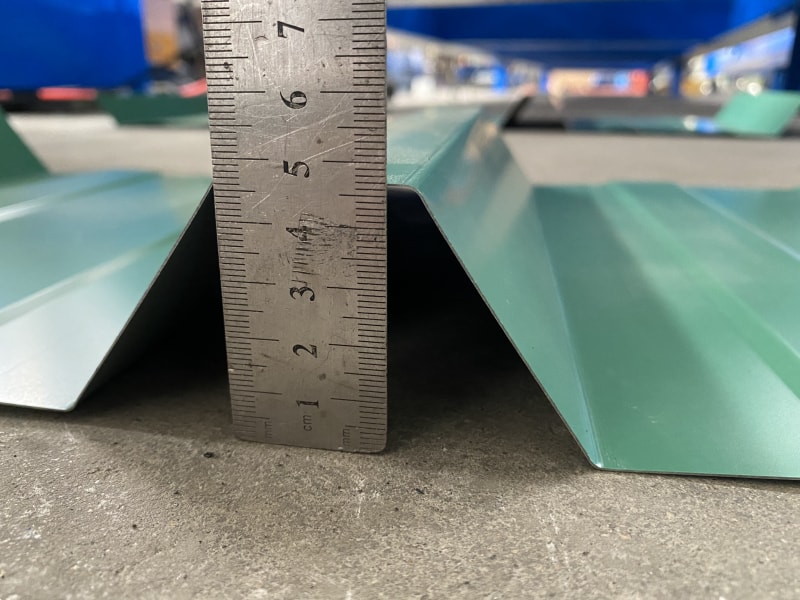

The equipment parameters are: single pulse length, overshooting amount, press distance, press time, cutter time and so on. User parameters are: number of sheets, length, first section, last section, pitch, number of sections and so on. Color steel tile press.

Color steel tile press machine must use high number of pulse input function, high number of input performance is excellent, select AB phase anti-interference ability. And use the fixed value interrupt function to ensure the precision.

Characteristics of tile press machine equipment: the equipment has the advantages of operation, maintenance, maintenance, and debugging of machinery, mold replacement is easy;

the whole unit automation control system adopts highly integrated network, so that the automation system performance is more superior;

the equipment adopts a high level of automatic control software, to achieve the production of information technology management in the process of straightening of the color plate produced by the tile press machine equipment, the profiles will be moved from the top, the bottom, the left, and the right, thus Requirements for straightening mechanism and the gap between the profile is relatively loose, straightening mechanism and the profile of the upper, lower, left and right surfaces can have a certain gap between the gap size in the 0.010-0.050in (0.25-1.25mm), if the straightening torsion deformation, the gap can be smaller .