Steel Stud Roll formers are the main type of machine for producing these steel framing studs and tracks. Also called stud and track rolling forming machines, a roll former can run at high speed and produce as much formed studs as required.

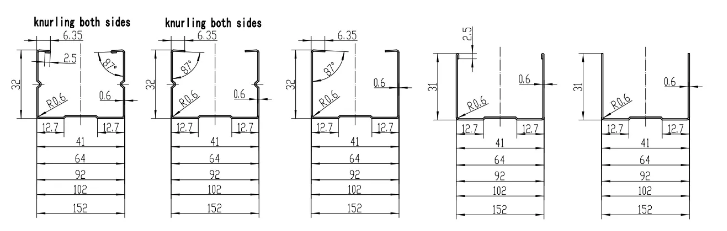

Stud and track roll forming machine from Cangzhou zhongtuo can be changed in 20 minutes or less to produce different width and flange heights in different gauges of material. An electro-mechanical adjustment is all that’s required to offer a wide range of stud and track widths on demand. With our stud and track roll former, you can produce studs and tracks in a wide range of material gauges and lip sizes from C stud 1 5/8 to C 6 and U track 1 5/8 to U 6 as gauge and sizes requirement.

Stud and Track Roll Former employs a precision flying shear to produce close tolerance parts on various widths and gauges of materials, you can choose by spacer change or tooling change or PLC change. For the speed, there is also 45m/min, 70m/min and 100m/min for you choose. All are custom designed and offer a variety of options for your specific application.

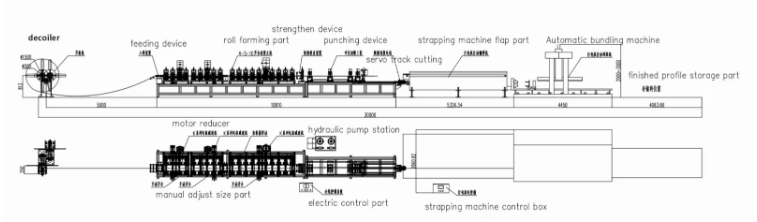

Drywall Metal Stud And Track Making Machine Production Process:

Material Coil – Decoiling machine – Roll Forming (Flying Punching) – Flying Cutting Off – Finished Profile.

Drawing for reference:

| NO. | Equipment | Specification | Qty. |

| 1 | Manual Decoiler | (1) Inner Diameter: Ø 460 – 510 MM | 1 Unit |

| (2) Loading Capacity: 1000 KGS | |||

| (3) Manual Operating Type: Manual Expansion To Tighten The Coil | |||

| 2 | Roll Forming Machine | (1) Quantity Of Rollers: 12 Groups | 1 Unit |

| (2) Roller’s Material: Cr12 Steel, Heat Treatment, Quenched | |||

| (3) Roller’s Surface Treatment: Polished | |||

| (4) Roller’s Main Shaft: Ø 40 MM, 40 Cr Steel, Quenched & Heat Treatment | |||

| (5) Bearing: HRB Bearing, Best In China | |||

| (6) Machine Side Wall: 25 MM | |||

| (7) Machine Base: Welded By 80 Square Pipe | |||

| (8) Driving Method: Chain & Gear Or Gearbox | |||

| (9) Coolant System: Equipped | |||

| 3 | Flying Cut-Off Device | (1) Hydraulic Pump Stand: 1 Set, Auto Start / Stop | 1 Unit |

| (2) Hydraulic Cut Modular: 1 Set | |||

| (3) Modular Material: Cr12Mov (CN Standard) / SKD11 (JP Standard) | |||

| (4) Length Tolerance: ± 1.0 MM | |||

| (5) TBI Linear Guideway & Ball Screws: 1 Set | |||

| (6) Hydraulic Components: Taiwanese | |||

| (7) Hydraulic Overload Protection Setting: Maxi. & Mini. Pressure, Pump Stand & Forming Machine Stops & Starts, With Wind Coolant System, Filter Function | |||

| 4 | Run-Out Table | There is manual and automatic one for you choose. | 1 Set |

| 5 | Control System | (1) Controller: Motion Tracing Controller, Single Axis | 1 Set |

| (2) Touchable Screen: 7” Color Screen, WEINVIEW | |||

| (3) Encoder: Omron, Japanese | |||

| (4) Button / Knob: Schneider, France | |||

| (5) Speed Control: Frequency Converter | |||

| (6) Power Supplier: 380 V, 50 HZ, 3 Phs; Customized |

For the hydraulic decoiler and stacker and bundling machine , please check the following photos, you can also tell us your request in details, we design it as your custom request.