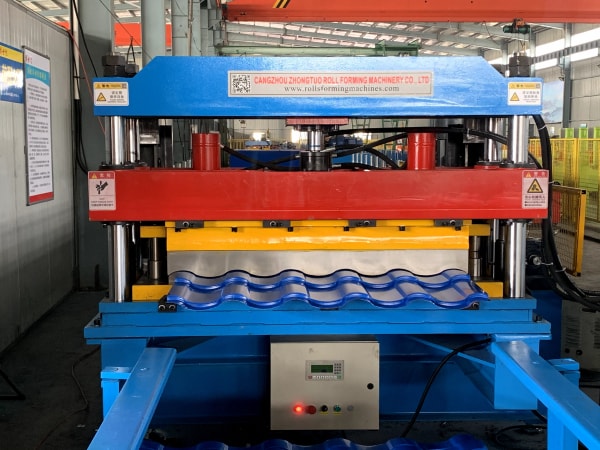

Adamante Roof Tile Making Machine

Design Idea:

Main Technical Parameters Of This Adamante Roof Tile Making Machine:

1)Material thickness:0.33-0.5mm

2)With 7ton hydraulic decoiler and loading car

3)14 rolling stations, main motor is 5.5KW

4)Both sides with 3D cutting

5)Gearbox driving, each station have one gearbox

6)Dleta brand PLC and controller

7)With 3m auto stacker

2)With 7ton hydraulic decoiler and loading car

3)14 rolling stations, main motor is 5.5KW

4)Both sides with 3D cutting

5)Gearbox driving, each station have one gearbox

6)Dleta brand PLC and controller

7)With 3m auto stacker

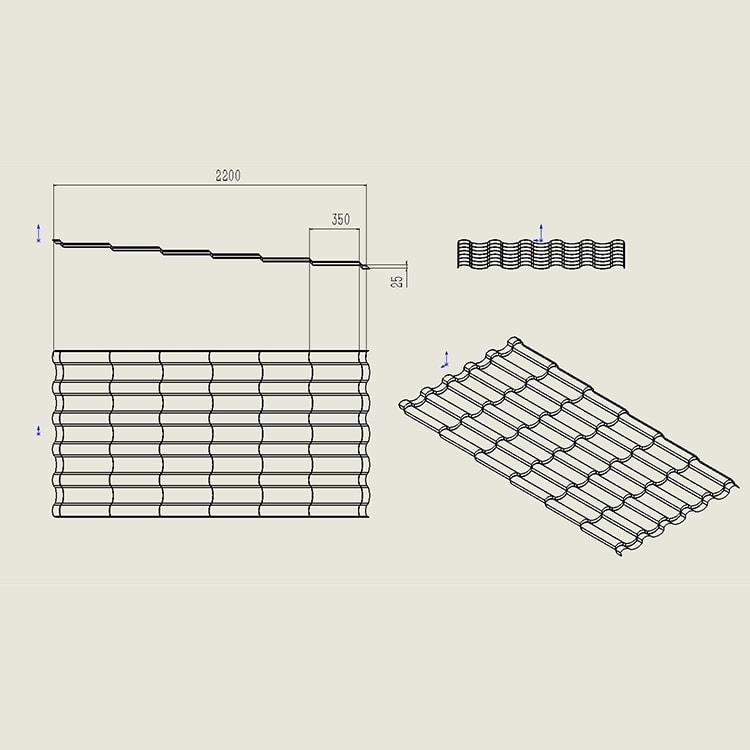

Profile drawing for reference:

Adamante roof tile has a specially profiled starting edge which increases the aesthetics of the roof.The clear and elegant shape of the profile perfectly emphasizes the character of the house. Here are some photos of adamante roof tile.

Processing Flow

For this Adamante roof tile making machine, client choose following production line:

Packing list- roofing profile roll forming machine | ||||

No. | Name | Unit | Quantity | Remark |

Part 1 | 7T decoiler with loading car | set | 1 | Automatic |

Part 2 | Main roll forming machine | set | 1 | Gear box drive |

Part 3 | PLC control station | set | 1 | Delta brand |

Part 4 | hydraulic system | set | 1 | For cutting |

Part 5 | 3M auto stacker | set | 1 | |

Part 5 | Spare parts | set | 1 | |

PRODUCT DISPLAY