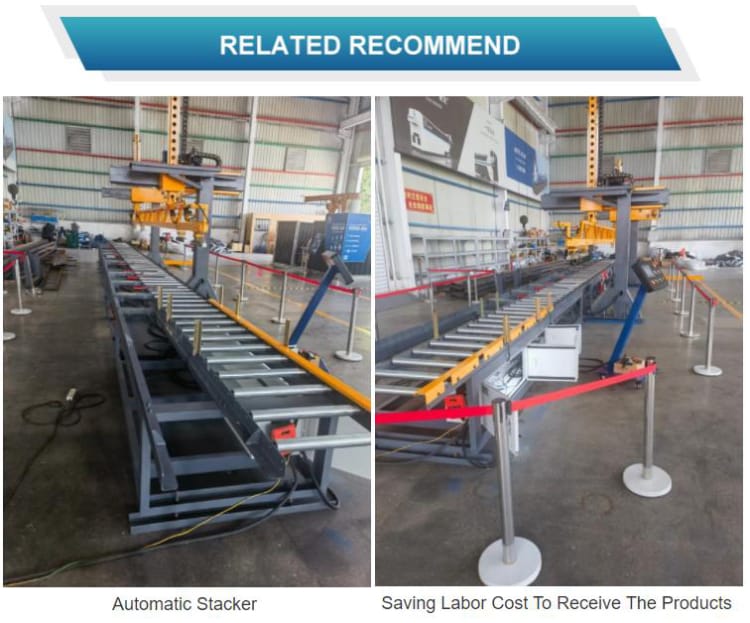

Video Description

Fully Hdraulic System And Fully Automatic CZ Purlin Machine

Design Idea:

Use Hydraulic hydraulic motor instead of normal power, that can save the working power , the size changing and C to Z changing driving by motor control by PLC , automatic adjustment method can let your stuff finished different specification Purlins.

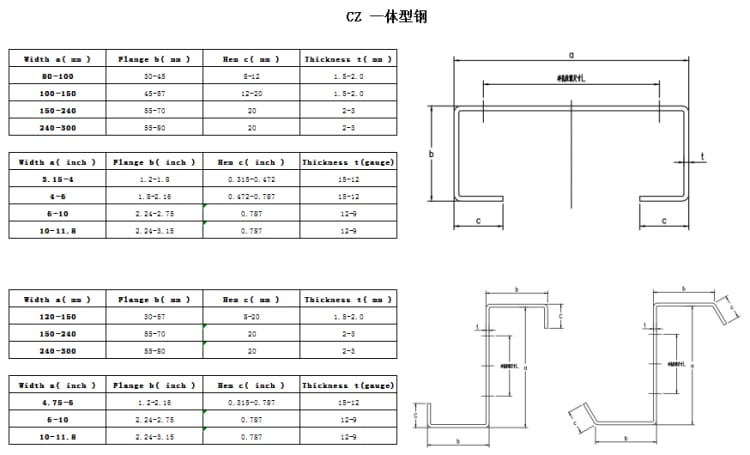

Profile drawing for reference:

Standard sepcification: Width from 80-300 mm(3-11 inch) , Thickness from 1-3mm( 15-9 gauge ) , other specail size we can also customized.

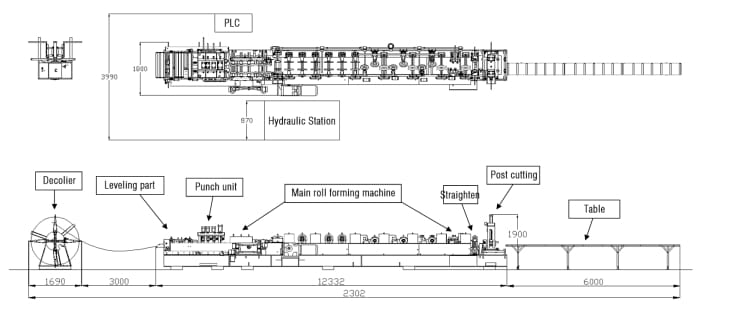

Processing Flow

Uncoiling → Feeding And Leveling →Punching/Pre-Shearing→Roll Forming → Auto Cutting →Products Receiving Table

Fully Automatic CZ Purlin Machine To USA | |

Raw Material | PPGI,PPGL |

Material thickness: 1-3mm( 15-9 gauge ) | |

Coil width :150-500 mm adjusted | |

Machine Frame | Machine base frame is made of U beam weld steel. In the main roll forming machine, there are 2 buttons for urgency stop in case any malfunction happens. |

Material Of Rollers | High grade 45# forged steel |

Roller material: Cr12 CNC processing heat treatment to HRC: 58-60 ,finish turning | |

Forming Stations | Roller stations :20 rows |

Diameter Of Shafts | Φ75mm solid |

Material Of Shafts | 40 Cr CNC processing HRC28-32 ,finish turning and electroplate |

Forming Speed | Max 30 m/min |

Voltage | 380v/50hz/3p (As Requested) |

Transmission Way | By 1.5 inch chain |

Hydraulic Power | 30KW (WK series Hydraulic motor) |

Cutting Blade Material | Gcr12 quenched treatment |

Cutting Type | hydraulic post cutting |

Control | Sizes adjust by PLC control and button C and Z section changing by PLC control |

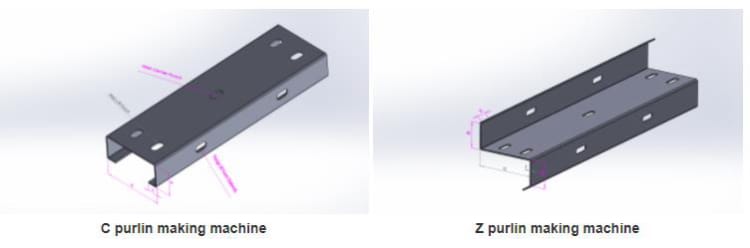

PRODUCT DISPLAY

5T Manual Decolier For Free Capacity:5 tons Coil inner diameter:450-550mm Feeding width: max 500mm Structure: welded by the steel plates and profiled bar. The shrink and expand of coil is automatic , Drive by Hydralic power. | |

Feeding And Leveling Device There is an electric button here, which can automatically adjust the feeding width Leveling rollers: 3 up 4 down Roller material: Cr15 Roller diameter: 75mm Feeding width adjustment: automatic by button Make sure inputted steel sheet straight and neat and then roll forming process could be made accurate | |

Roll Forming And Transmission Device Rollers material:Cr12 CNC processing heat treatment to HRC: 58-60 ,finish turning Roller stations: 21 rows , 12 unit roller stations for C and Z changing. Shaft material:Shaft material: 40 Cr CNC processing HRC28-32 ,finish turning and electroplate Drive by Heavy duty chains: 1.5 inch | |

Hydraulic Cutting Device Material of blade: Cr12mov quench treatment Length measuring: automatic encoder measuring,Tolerance of length is 3000mm+- 1.0mm You can manually adjust the cutter to cut different sizes of c/z purlin. You do not need to change new blade and this cutter is easy to operate. | |

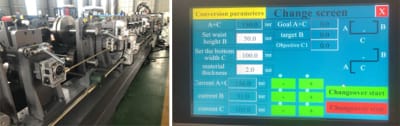

PLC control system PLC brand:Delta(Taiwan) PLC, and transducer and touched screen ● Encoder brand:Omron ● Electrical components:Schneider ● Operating language:English and Chinese(or as requested) You can set the orders on this part,changing product length and quantity,it is really easy to operate,and there are aviation plugs to make it much easier to install the machine while it arrived. |

OUR ADVANTAGE

1.Hydraulic Motor Hydraulic motor, lower cost and lower power wasting . | |

2.Fully Automatic Changing These motors can drive the machine frame, these motors control by PLC, so you just touch the screen , sizesing changing or C to Z changing can be controled automaticly. | |

3.Puching Unit With Hydraulic System Station 1: Pre-Hydraulic shearing Station 2: Bottom center holes punching Station 3: Bottom double side holes punching Station 4: Each side fleg holes puching |