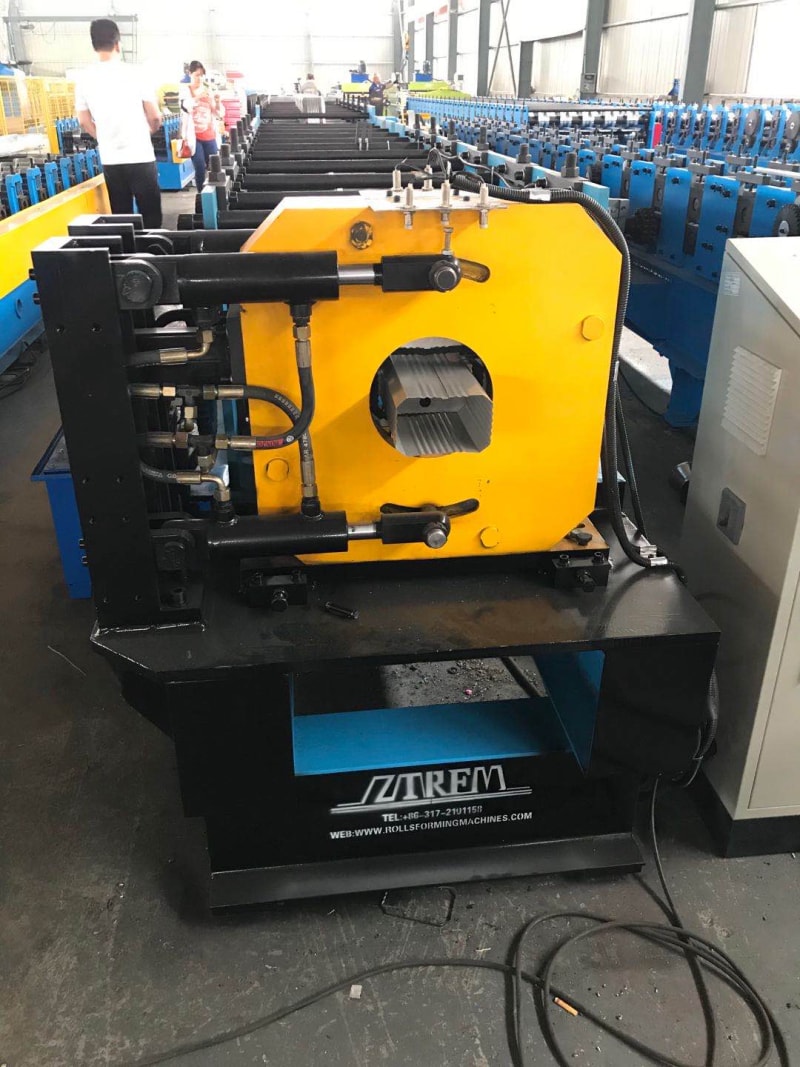

fully automatic downspout roll forming machine for building system

machine brief introduction

Automatic building system round/rectangular downspout roll forming machine (square or round, rectangular or round) technically can be operated manually or automatically according to the needs of different customers, manual operation is required for installation or use The time is longer, and the automatic operation is for continuous production of downspouts. It usually consists of manual decoiler, feed rail, roll forming machine, cutting tools (for hydraulic cutting of round or rectangular downpipes and flying saw cutting machine for round or rectangular downpipes), transmission system, PLC control cabinet It is composed of a finished product output station, and there will also be an elbow machine for customers to choose.

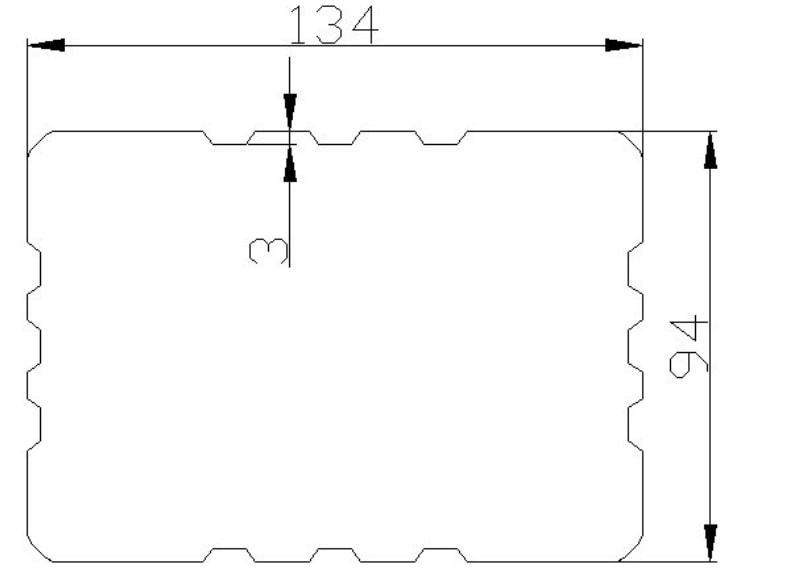

final product showing

application of this downspout roll forming machine

application of this downspout roll forming machine

main components and machine techinical parameters

Uncoiler, forming part finished product output table, PLC control station, hydraulic station

Manual Uncoiler

Inner diameter: 508mm

Outer diameter: 1200mm

Loading weight: 3T

Downspout Roll forming machine

Material thickness: 0.4-0.6mm

Rolling station: 20 stations

Forming speed: 10-15m/min (not including cutting)

Shaft diameter: ¢60mm

Transmission: through chain support

Main power: 7.5KW

Machine weight is about 5 tons

Cutting type: round downspout Flying saw

cutting hydraulic power: 3KW

Cutting blade material: quenched Cr12 steel

Cutting length and quantity: customers can set the required length and quantity on the PLC touch screen

Electrical system: Panasonic PLC control system and Omron encoder