Our ZT-P300 C Z purlin machine driven by gearboxes or Chains, consists of decoiler, feeding and levelling device, punching system, pre-shear, roll forming system, hydraulic post cutting, run out table, hydraulic station and PLC(controlling system).

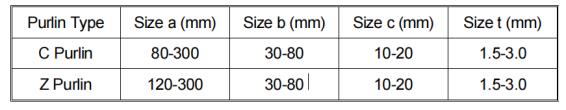

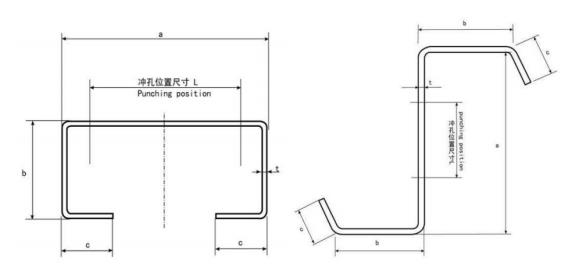

Its special feature: Assemble with liner guide way to make machine change web size easily and smoothly, Produce standard products with yield strength up to 550Mpa,Large range web size is 80-300mm and thickness up to 3mm, which used widely and would be the most popular model in the near future.

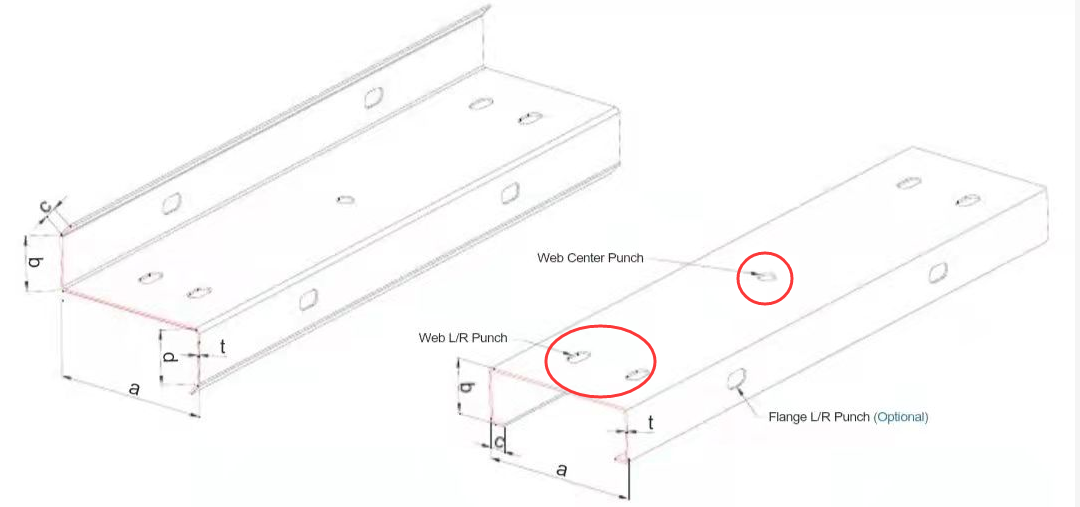

The purlins Normally use for warehouse bulding, this also need prulins connetting by holes, we also need puching holes on the purlins:

How to set the holes sizes and hole distance?

The machine has designed the setting of four punching stations. The setting value of the each punching position on the screen is the distance from the beginning of the formed product to the punching hole center. Each punching station can set 90 values, which means that you can punch 90 holes of the same size at different positions on one product.

How to change different hole molds?

The upper and lower dies of the punching die are fixed by bolts. When punching holes of different sizes need to be replaced, they can be easily replaced by removing the bolts.