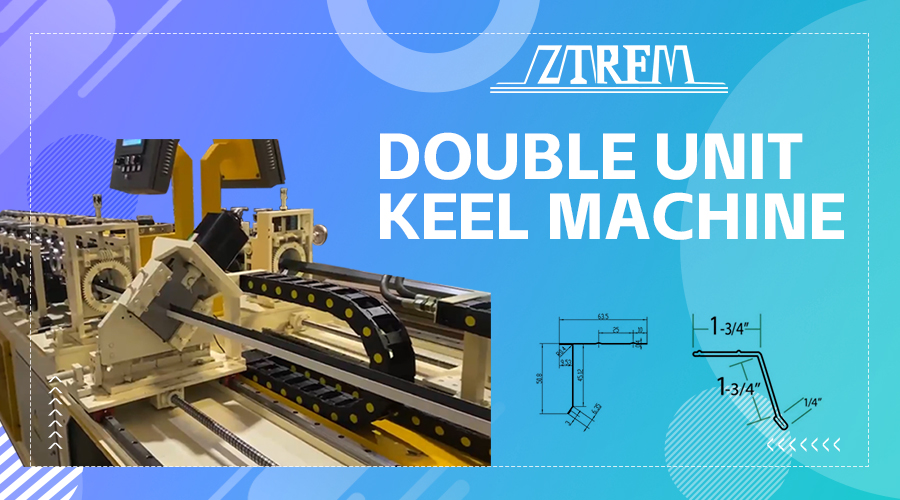

The keel machine uses strip steel as raw material and is formed through continuous cold rolling to produce complex cross-sectional profiles (products include: light steel keel, painted keel, card type keel, various building profiles, steel structures, steel lined door frame profiles, high-speed guardrails, etc.) and different specifications of cold bending and painting equipment, which are controlled by PLC.

The characteristics of the keel machine:

1. The equipment is controlled by PLC and is equipped with multiple safety protections during normal production.

2. The bed is made of steel plate and subjected to tempering treatment to avoid deformation of the body.

3. The formed frame is made of cast iron structure and has undergone tempering treatment. High strength and long service life.

The material of the roller shaft is 40Cr, which has been quenched and tempered, and the hardness is HB280.

5. The material of the forming mold is GCr15, quenched, and the hardness is HRC56-62 ℃.

6. The transmission structure is gearbox transmission. Each forming frame has a light steel keel machine. It can ensure that the equipment exceeds the time limit and has a long service life.

The processing technology of the keel machine: discharging – straightening – rolling forming – cutting – receiving

The composition of the keel machine equipment includes a feeding machine, a guide frame, a forming host, a calibration device, a fixed length cutting section, a receiving table, and an electrical control section.