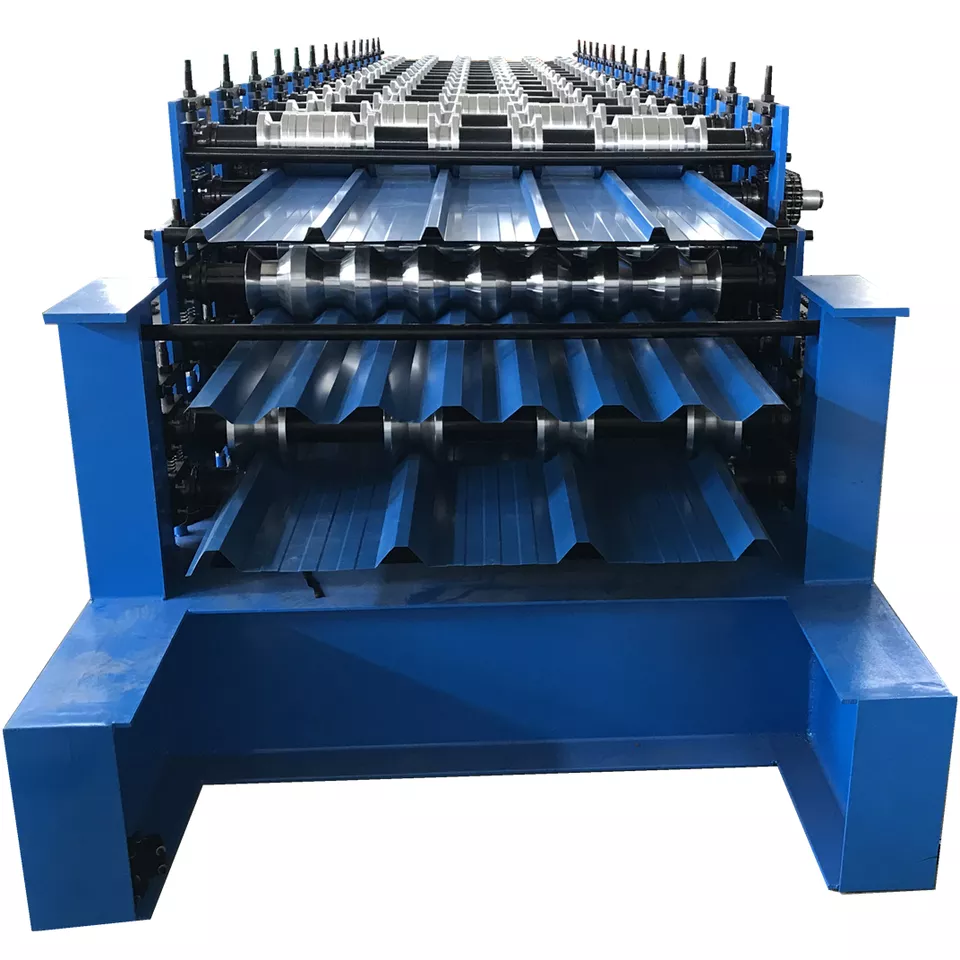

This is the machine to produce the Metal steel roofing panel,one machine can produce 3 types.This design of the machine can save customer’s factory space,and compare to 3 individual machines,this machine’s cost is a little lower too.

The component of the whole Three Layers Roll forming machine:

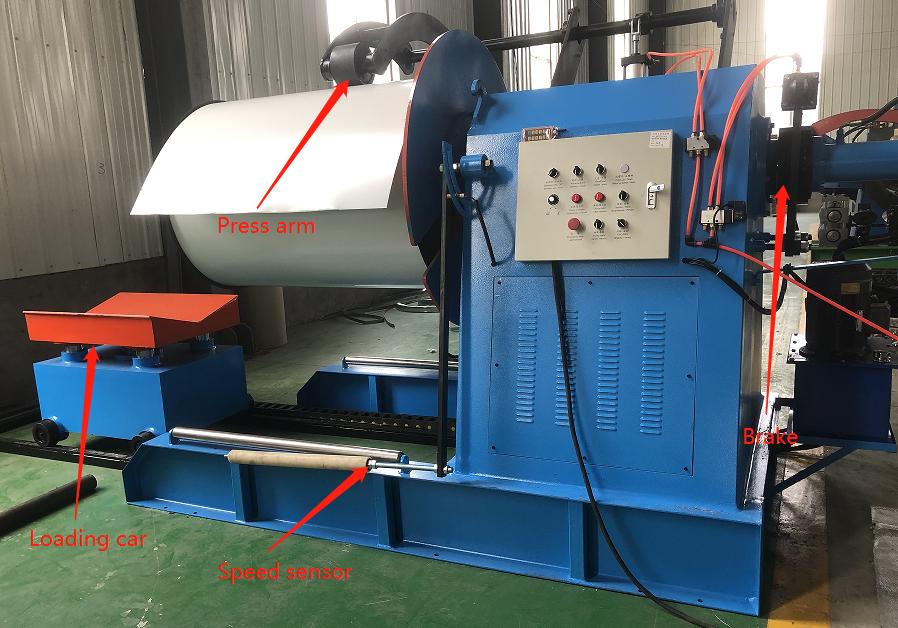

1.Decoiler

2.Three layers roll former

3.Hydraulic cutting system

4.Control system

5.Product receive table

The detailed introduction of the Three Layers Roll forming machine:

Part 1:Decoiler

- Capacity:5 tons(support customization)

- Working type:Automatic type and manual for option

Part 2:Three Layers Roll former

- Machine structure:350#H steel welded,with 20mm middle plate welded

- Roller station:16+17+19 stations

- Roller material:45# steel,surface with chromed to improve the hardness of the roller

- Shaft diameter:80mm,solid

- Motor power:7.5kw

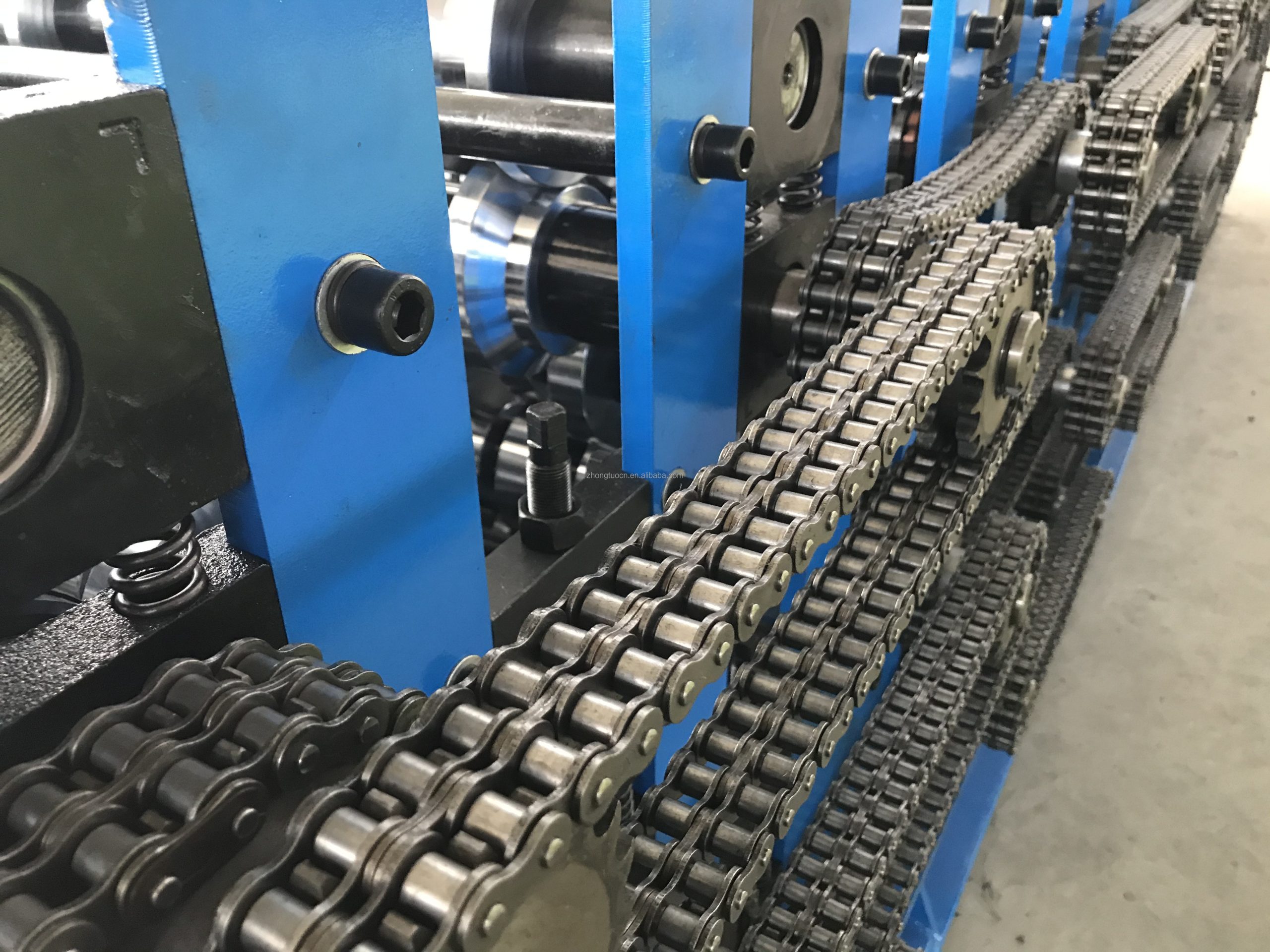

- Transmission:By DOUBLE chains

Part 3:Hydraulic cutting system

- Hydraulic power:5.5kw

- Cooling system:By fan,to cool down the oil temparature during long time working or in hot weature

Part 4:Control system

- Control system:PLC

- Function:To control the panel length,quantity and batch,and control the speed of the machine

- Encoder brand:Omron

- PLC,touch screen:Delta/Siemens/Mitsubish

- Language:Chinese-English-Spanish-French-Arabic

Part 5:Product receive table

- Length:3 meters,or customized

- Working type:Manual or automatic for optional