Product Overview

Stacker for the metal rolling forming machine

Stacker for the metal rolling forming machine is the tool for making the profiles from the machines orderly and then package them well. It can help you save one or two workers and enhance the working production rate. For the stacker, we have light duty, middle type and heavy duty types. For example, the stacker for the C Z purline machine, the stacker for high speed stud and track machine, the stacker for the tube lines and the stacker for the highway guardtail rolling forming machine. In the following part, I will take two types stackers for example. If you need other types, please message us and then we can customize for you.

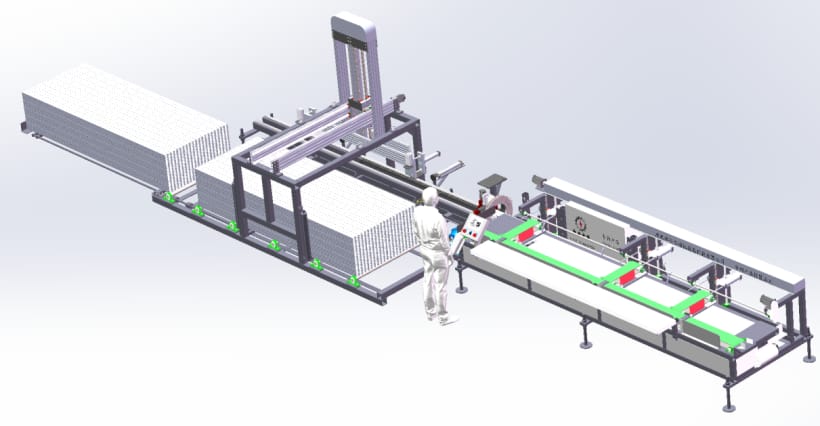

The stacker for the C Z purline machine

Functions of stacker: For modern factories, fully automatic production lines have been used, and automatic palletizing is indispensable: Improve work efficiency,automatically stack the purlins neatly. 1.Save labor cost, no need use the two wokers to received the products all the time. 2.When when all the purlins are neatly stacked, use a forklift to move it. 3.Machines replace labor, saving factory operating costs in the long run. 4. Improve safety factor,staff will not scratch their hands due to direct contact with the prulins.

Why you need stacker?

| 1.When planning to use the higher speed rolling forming machine, workers can not handle so higher speed. | ||||

2.When you handling the thickness beyond 3.0mm, or mostly heavy duty work. | ||||

| 3.When the worker salary is higher, the stacker can help you save workers one or two. | ||||

| 4.When the production is so high, stacker can help you do the purline orderly. | ||||

| 8.Package system, with manual option and fully automatic system. |

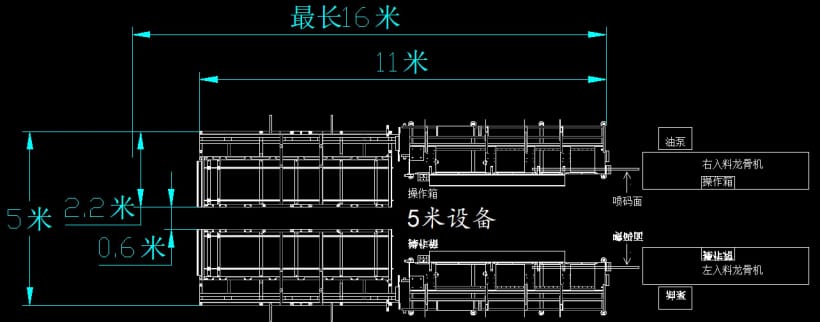

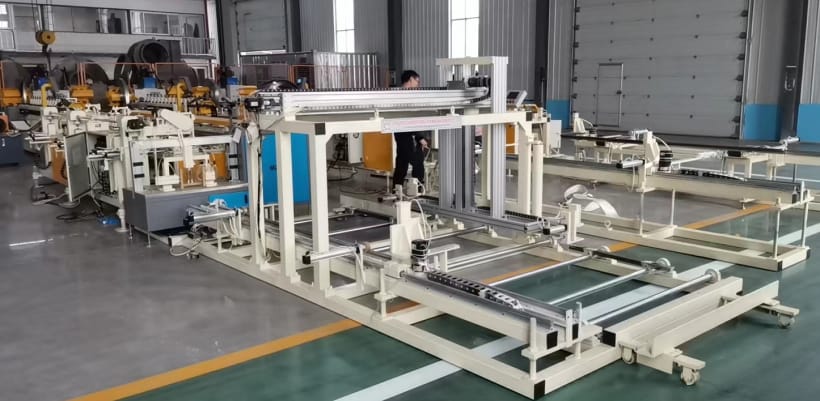

The stacker for high speed stud and track machine:

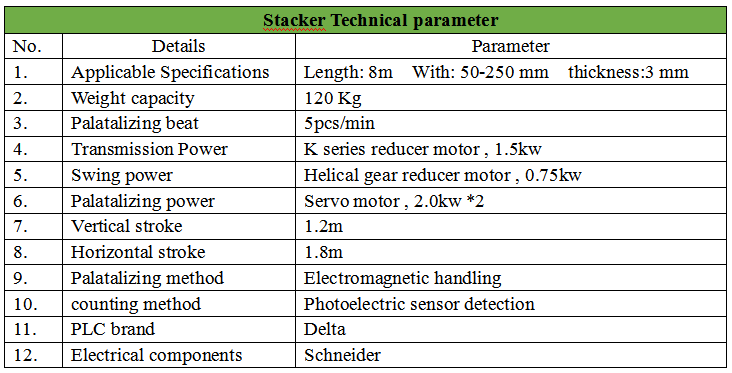

Main elements and parameter

①Before feeding and flip over part Name Illustration Frame body 60x60x3 square tube welded conveyor All adopt thickened non-slip conveyor belt Feeding horizontal push All adopt SC cylinder and rubber soft head to effectively prevent the keel from scratching Fastening piece: Laser cutting process transmission shaft

Using 30 diameter 45# steel, the surface is plated and processed slide All use precision square rails Lifting screw 25×25 Ball Screw Storage lift: servo motor Push the material and push all: Servo motor is power, chain drive is adopted for better flexibility

②The winding part Frame body: CNC cutting of 25 thick iron plates Tape rotation power:Servo motor and slewing ring gear drive Tape fixed shaft: Cooperate with slewing bearing to rotate, spring compression and elasticity can be adjusted Winding clamp: Double rod cylinder is used to prevent rotation and make the bag shape more square

③Pulling part Frame body: 80x80x3 square tube welded Mobile power Servo motor supporting reducer and rack and pinion drive slide Using 45# steel, high-frequency heat treatment surface plating processing, matching sliding block, square guide rail is more stable Pull material clamping Double rod cylinder is adopted, the air pressure can be adjusted individually, and the air pressure can be adjusted according to the material thickness to prevent the keel from deforming

④tagging part GPS Optical fiber detection, manual adjustment, flexible operation and precise positioning power High-power speed-regulating motor, stable operation Take bid Adopt vacuum sucker, easy to operate, stable performance Paper supply tray Adjustable paper supply tray, the elastic screw can be adjusted according to actual needs, simple and convenient

⑤ Stacker part : Frame body 80x80x3 square tube welded Manipulator body Assembled by thickened heavy-duty aluminum profiles Manipulator The clamping type after reclaiming is adopted to ensure the firmness of grasping and the stability of movement Stack mobile roller Using 45# steel, the surface is plated with Luo, φ45 mm solid Rotating ruler roller for discharge In order to ensure the squareness of each stack of keels and do not scratch the keel when moving, a round ruler roller is selected and a rotating bearing is installed inside

PLC control name Qty Brand and Mode PLC 2 Fuzhou Maintenance PLC extension 1 Fuzhou Maintenance touch screen 1 Fuzhou Maintenance Proximity switch 7 NPN, 24VDC, normally open Photoelectric switch 4 NPN, 24VDC, normally open Incoming photoelectric 1 Background detection sensor Effectively suppress feed interference Broken belt detection photoelectric 1 Transparent object detection sensor Scotch tape available Barometric pressure meter 1 24V, normally open Can detect low air pressure alarm Relay 32 Izumi, Japan Switching power supply 2 MEAN WELL servo motor 7 set Flextronics 0.75KW (5 sets) Famous brand products of listed companies Frequency converter 1 set Flextronics 0.75KW brake (2 sets) Operating power Flextronics 2.2KW If you need other type stacker, please contact me at any time and then we can customize for you.