Simple Metal Coil Slitting Production Line

Slitting machine is used to slit PPGI coil, aluminum coil, galvanized coil, stainless steel, carbon steel and other coils into several small strips along the length direction. The slitting ling mainly consists of uncoiler, leveling system, slitting system, shearing system, damping structure and recoiler and so on. We can design and manufacture different specification according to different requirement of the client.

Here I will introduce one type slitting line for the thin sheet. It could be used to process the thickness from 0.2 to 1.2mm and the coil width to 1250mm width.

The machine slitting speed can reach 15 to 20 meter per minute.

Main specification:

| Project | Parameter | |

| Specification | Material | PPGI, GI, Al, copper etc. |

| Thickness | 0.4-1.0 mm | |

| Width | 500-1250mm | |

| OD ID | φ1300mm Φ508mm | |

| Weight | 5 T | |

| Slitting accuracy | Width tolerance: Longitudinal tolerance Burr | 0.10mm ≤1mm/m ≤0.03mm |

| Way of cutting | Feed cutting | |

| Slitting strips | Max. 10 strips | |

| Stripe width | Min 60mm | |

| Re-coiler diameter | Φ508mm | |

| Speed | 0-20M/min | |

Simple slitting line more details functions for your reference:

| 5 Ton manual decoiler | Supporting coils and doing uncoiling, passive type, the core moving forward or reverse is pulled by slitting machine. Shrink and expand core manually. Carrying capacity: 5 tons Core inner diameter: 450-550mm Max coil width: 1250 mm Structure: Steel channel welded for the basic frame, profiled bar Advantage: by a big wheel. with manual brake, so operate more easily |

| Straighten leveling, slitting with cut to length machine | Input : 1250mm Thickness : 0.4-1.0mm GI, SS, Aluminum, film coated sheet Rollers : 3 up 4down,2 input Shaft: Φ110mm Wall panel: 25mm, A3 400H steel frame Power: 7.5 kw Speed: 16m/min Hydraulic power: 5.5 kw. Driven : Chain Cutting blade and slitting blade: Cr12 Slitting : max. 10 pcs The machine can straighten leveling then cut to length Voltage, Frequency, Phase: 220 V, 60 Hz, 3Phase (this is can depend on customer request) Solenoid valve: YUKEN |

| Cutting | Cutting motion: The main machine automatically stops and then cutting. After the cutting, the main machine will automatically start. Material of blade: CR12 , cut form down to up. Length measuring: Automatic length measuring Tolerance of length: 10+/- 1.5mm |

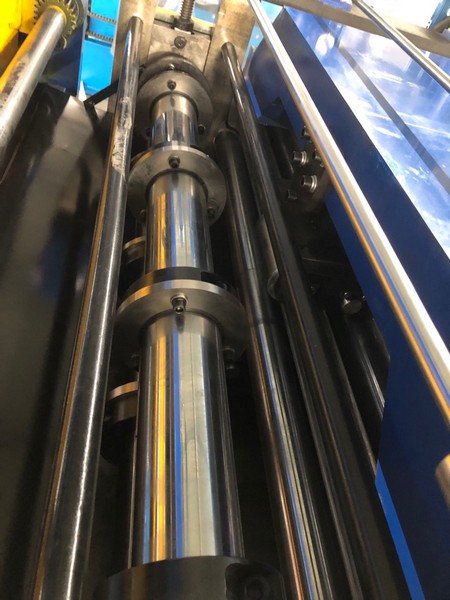

| Metal slitting part will be like this. | |

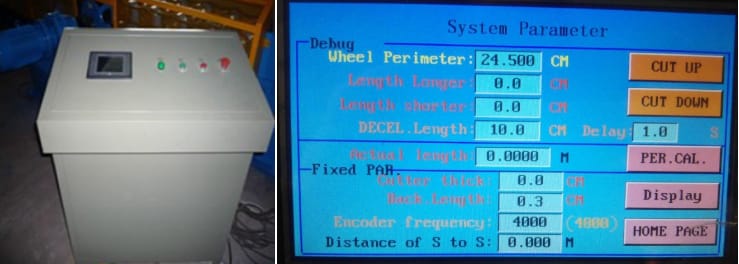

| PLC control system | Voltage, Frequency, Phase: 220 V, 60 Hz, 3Phase (this is can depend on customer request) Control panel: Button-type switch and touch screen PLC : KAUTO Touch screen: MCGS Frequency converter: DELTA |

| Damping Structure | Provide tension force for the metal strip after slitting, so that it can be more neatly and tightly re-rolled into a steel coil on the winder. The felt of the clamping mechanism can well protect the metal surface from scratches. |

| 5T Hydraulic Recoiler | Reqcoiler form : 5 tons hydraulic recoiler with trolley ID of Coil: ø 508mm, Max Width : 1500mm Max. Weight : 5T Hydraulic power: 4 kw with air cooling system Voltage, Frequency, Phase: 220 V, 60 Hz, 3Phase (this is can depend on customer request) A nylon plate is installed on the trolley table surface, which can effectively avoid scratches on the painted surface of the steel coil during loading and unloading. |

| Color of the machine | Blue (or as request of client) |