Generally, on a semi-automatic c or z shaped channel roll forming machine, there are three separate rolling tools installed on three sub-frame which can move horizontally.

Like a traditional c or z steel purlin roll forming machine, this semi-automatic roll forming machine makes different c or z shaped section channels by manual changing. However, on a traditional c/z purlin roll forming machine, we change spacers between rolling tools, while on a sem-automatic machine, operators just move the respective sub-frames to adjust for different sizes of web heights or flanges.

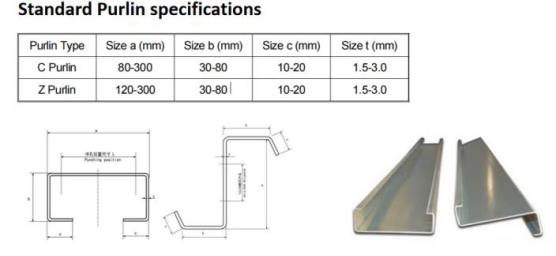

Our standard CZ purlin machine can do these specifications:

The CZ prulin machine can build some building metal structures :

Some size C purlin can as the solar structures:

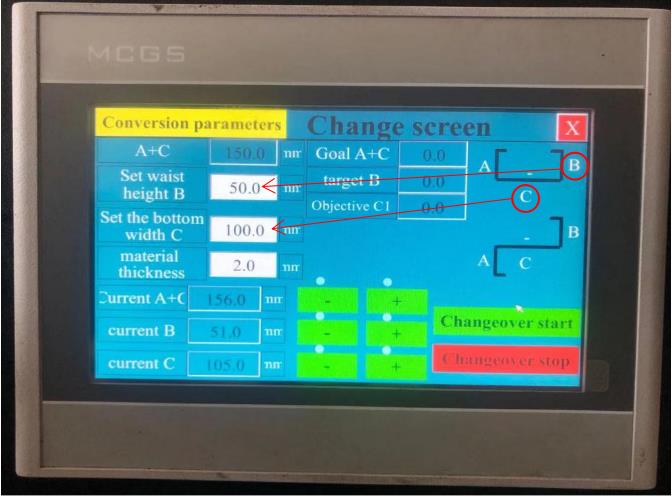

How to adjust the sizes by PLC operation? Expect PLC setting what other work we should do?

Input the height and bottom width of the product you want to change and the thickness of the material used in the white background input box on the screen, click changeover start, and the size adjustment motor starts to automatically adjust the roll forming parts to the required position.