Rack Upright Roll Forming Machine

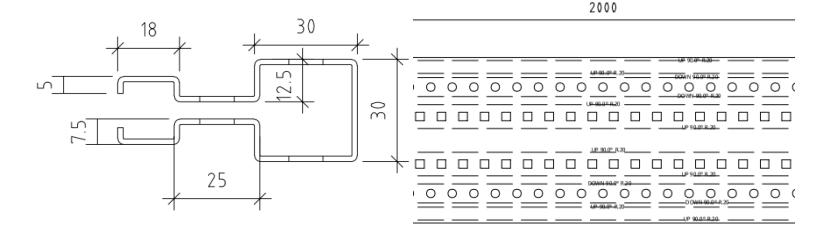

Rack Upright Roll Forming Machine is designed to make the rack upright profile in batch fully automatically. Storage pallet racking is a common storage device used to store and organize goods in a warehouse or industrial setting. Here are some general dimensions and accessories for storage pallet racks and I take a random one drawing profile for your reference and then share more information about how the Rack Upright Roll Forming Machine is designed:

This design is quite special like other upright profiles but the working principle is same. This machine takes galvanized steel or cold rolled steel as the raw materials,

through the a series steps to form it into a shelving profile with specific shape and size.

The forming steps devices include decoiler, Feeding and Leveling Device,

Hydraulic Punching device,main forming mill, hydraulic post-cutter.

The inverter controls the motor speed, the PLC system controls length and quantity automatically,

therefore, the machine achieves a continuous automatic production,

which is the ideal equipment for cold roll forming industry.

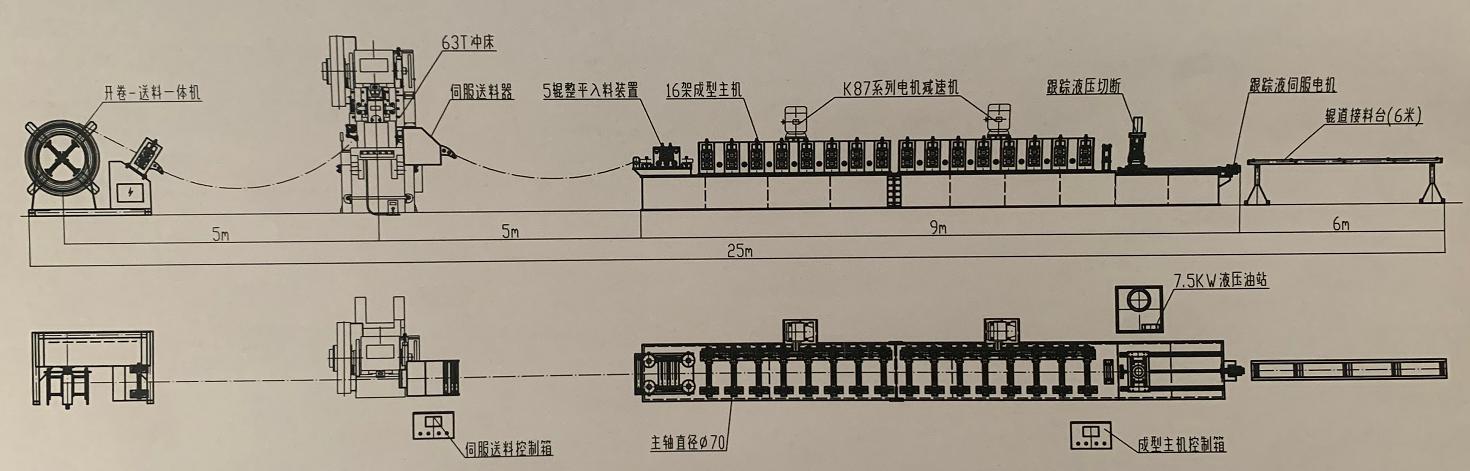

NO.2. Flow Chart of Rack Upright Roll Forming Machine:

Decoiler →Feeing and Leveling Device→Hydrualic Punching device →Main forming machine

→ Hydraulic post-cutting→Exit rack.

| Punching machine | Punching power | 80T |

| Feeding Part | Pressure roller material | Stainless steel |

| Feeding width adjustment | Manual | |

| Main roll forming machine | Voltage | 220V 60Hz 3Phase (as customer request) |

| Frame type | Molding frame | |

| Drive mode | 1.2 inch Chain with Gear drive | |

| Material of rollers | GCr12 Quenching | |

| Material of shafts | 45# steel with tempering | |

| Diameter of shafts | Φ80mm | |

| Number of rollers | 20 rows of roller station | |

| Main motor power | 11 kw + 11 kw | |

| Material thickness | 2.0mm | |

| Forming speed | 10 m per minute |

As to the punching machine, you can choose the type you like, here is one example for your reference:

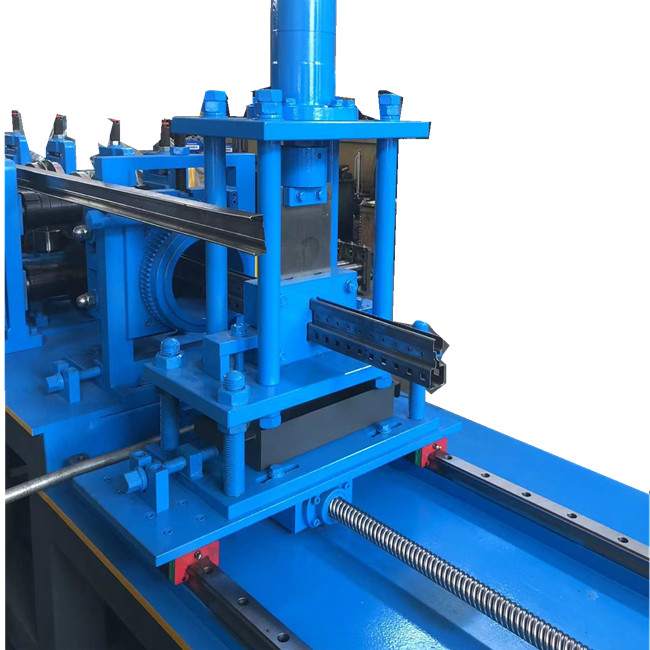

Roll forming machine combined with body frame, transmission mechanism and forming rollers, etc.

a)The body frame is side wall type: main shaft diameter φ75mm,made from 45# steel, heat treatment. The lower shaft is main transmission by gear chain.

b)Transmission by motor driving, gear chain transmission or you can

c)Rollers manufactured from bearing steel GCr12move, you can call it as D2,precision machined ,hard Chrome Coated,HRC50-60 with high durability

- d) Body frame made from H450 type steel by welding with beautiful appearance, natural aging treatment and SR(stress relief) treatment.

- We design with the molding frame thickness is around 35 to 45mm, more steady and long time to use.

- We design with protection cover.

3.With turkey head for straight when making.

Now we can check the shearing system.

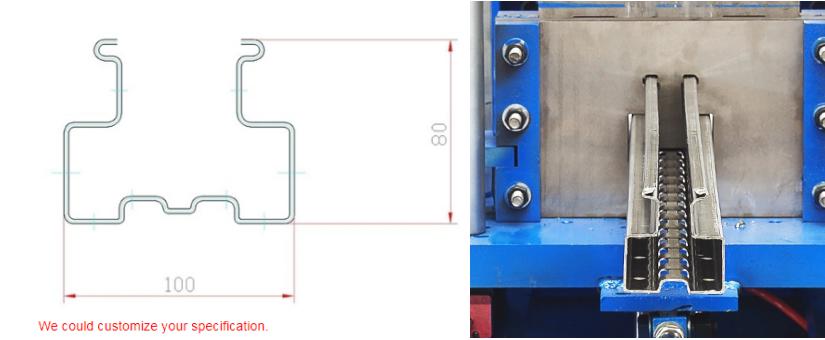

And there are more other profiles for your reference:

And those machine, if you need to know more information, please contact us at any time.