Double Layer Roof Sheet Roll Forming Machine

Design Idea:

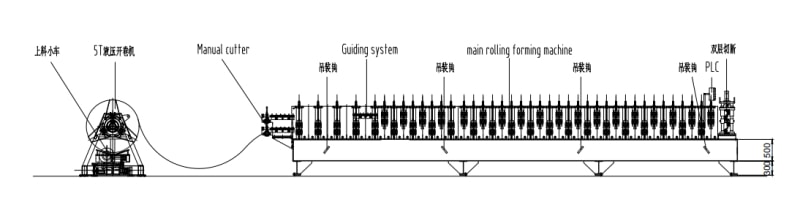

Stable Transmission: Double chain and gear drive,keynote rollers design.

Product Diversity:Can produce two different product in the same machine ,can save less space.

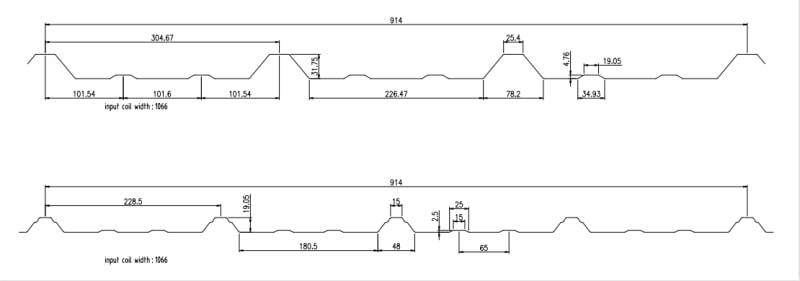

Profile drawing for reference:

Processing Flow

R Panel Roll Forming Machine Hot Sale To America | |

Raw Material | PPGI,PPGL |

Material Thickness:24/26 Gauge (0.4-0.6 Mm) | |

Machine Frame | 350mm H Beam Structure, With 18mm Welded Steel Middle Support Plate. |

Material Of Rollers | High grade 45# forged steel,Chromed treatment |

Forming Stations | Up layer :16 rows,lower layer:17 rows |

Diameter Of Shafts | Φ80mm Solid |

Material Of Shafts | High Grade 45#,With Heat Treatment |

Forming Speed | 15 M/Min |

Voltage | 380v/50hz/3p (As Requested) |

Transmission Way | By 1 Inch Chain (Double Chains) |

Main Motor | 5.5 KW |

Cutting Blade Material | Gcr12 quenched treatment |

Cutting Type | hydraulic post cutting |

Driving Method | By pillar type Cylinder |

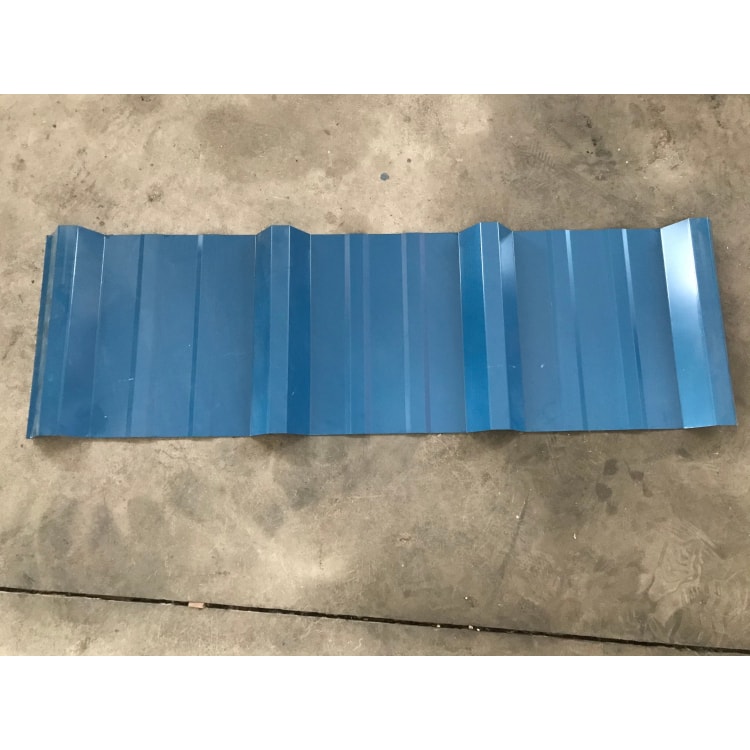

PRODUCT DISPLAY