NC SYSTEM Hydraulic Press Brake

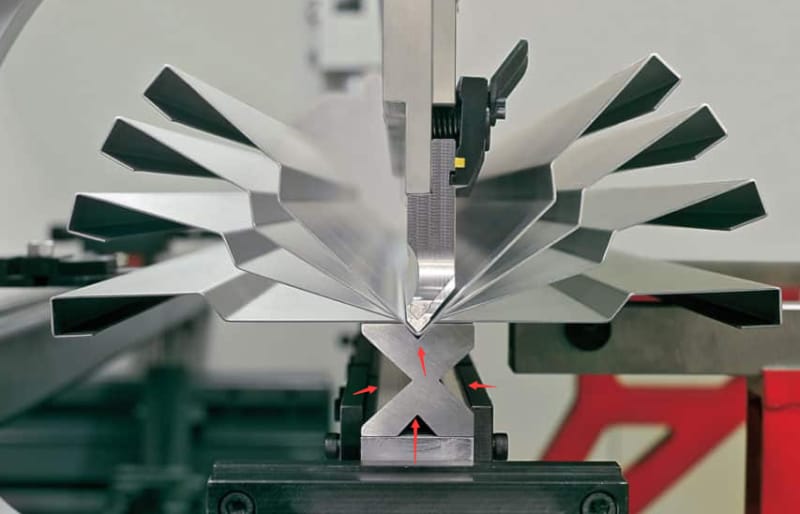

NC SYSTEM Hydraulic Press Brake is also called as the CNC bending machine which is used for bending the metal to the specified shape or profiles. By the mold and pressure power to bend the metal to the specified shapes. As to the NC and CNC, all we could make, no matter which type you need, we can design for you. Now we introduce the NC SYSTEM Hydraulic Press Brake for your reference:

Different with the rolling forming machine, be the bending machine, you can bend any types but you need to bend angle by angle, one by one the working process will be a little complicated and speed will be a little slow. For those profiles, where the demand is not huge, but you need various types, the pressing machine is good for you. Here is the machine pictures and parameters for your reference:

NC SYSTEM Hydraulic Press Brake | |

| Nominal pressure | 630KN |

| Bench width | 3,200mm |

| Pole distance | 2,400mm |

| Throat depth | 250mm |

| Slide stroke | 100mm |

| Max. Open height | 340mm |

| Main motor | Type: China shuangta Y132M-4 |

| Power:7.5KW | |

| speed:1460 r/min | |

| Pump | Type:SUNNY CPO-16-P-10R |

| Pressure:31.5mpa | |

| Rated:16Ml/r | |

| Dimension (L*W*H) | 3400*1700*2200mm |

| Weight | 4,500kg |

Standard Features

- Hydraulic oil circuit all with plumbing bite fittings or high pressure hose type

- Downstroke bending beam,actuated by two cylinders

- Rigidly welded, monoblock steel frame for minimum deflection under load

- Ram travel fully supported in low friction pertinax slideways, which are easily adjustable

- Patented hydro-mechanical system for exact parallelism and a high repeat accuracy

- Solid torsion-bar linkage for ram leveling

- Ram stroke control by precision mechanical-stops built into each cylinder and electrically adjusted by push-buttons with a digital position display on nc control panel

- Independent position control of one cylinder-stop to provide fine angle adjustment and/or conical bending possibility

- High stroke and daylight values to accommodate tooling variety

- Pressure switch and gauge to regulate bending tonnage easily and to prevent over bending due to bottoming of tools

- Hydraulic overload protection

- Pre-set, two-speed bending cycle giving fast approach, slow bending and fast return

- 3-function footswitch: normal bending, beam pause at any stroke point, automatic beam return upon release of footswitch