Metal Profile Stud Rolling Forming Machine

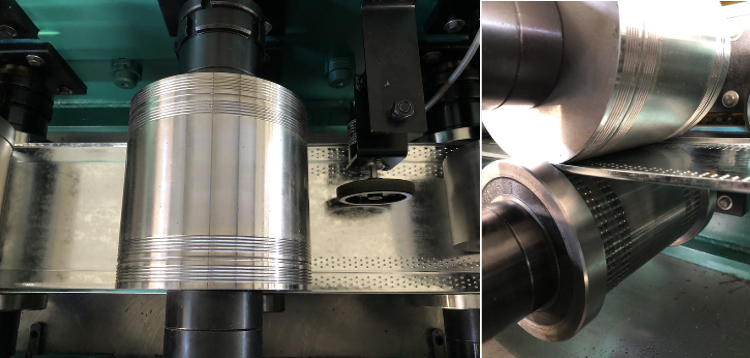

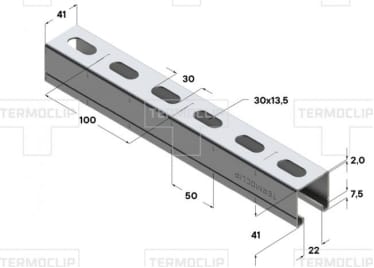

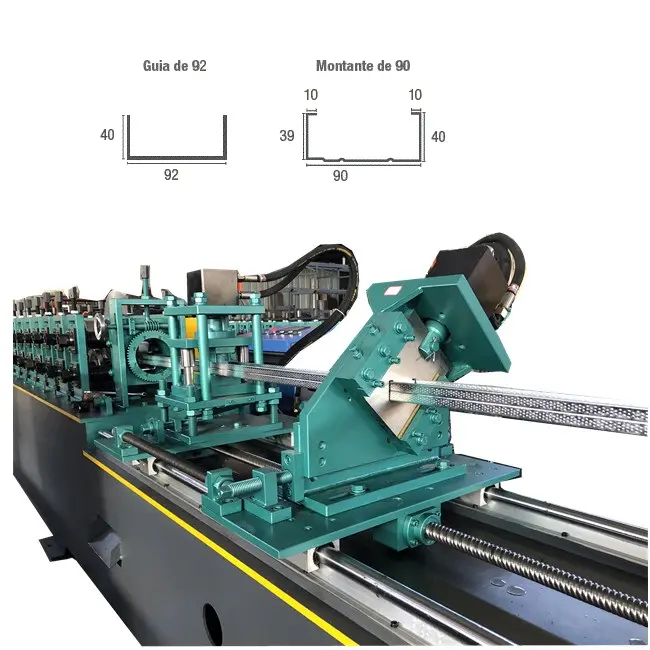

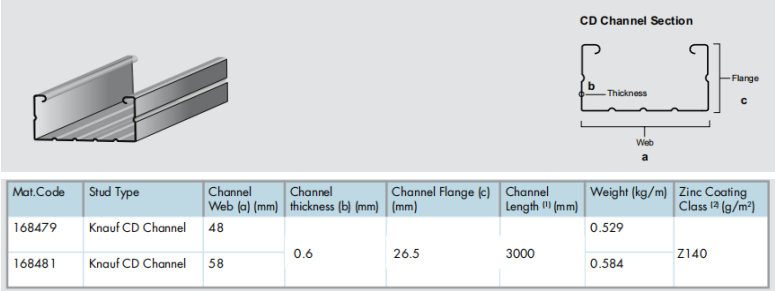

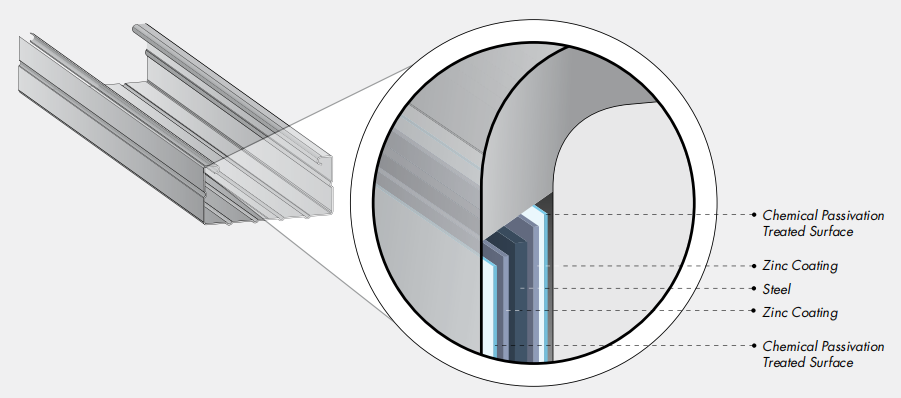

Metal profile stud rolling forming machine is designed to make the metal profiles in batch fully automatically. Metal profiles are precision-engineered, high-quality steel sections that are used to form the metal substructure of the Drywall or ceiling Systems. All metal sections produced from high-grade hot dip galvanized steel coils with the cold rolled forming process by the rolling forming machine. Here we will take some random drawing to show you how the metal profile rolling forming machine is designed.

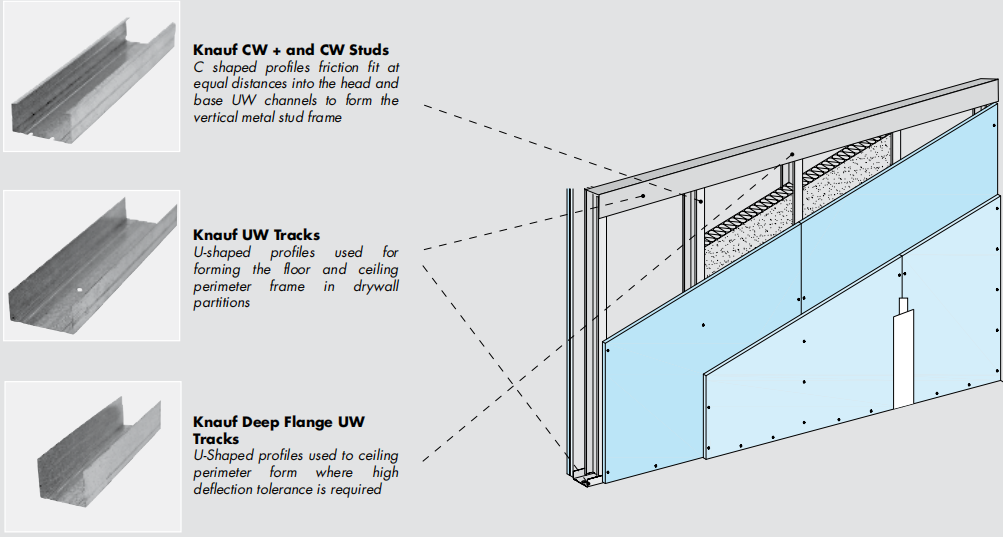

Sturdy 0.6 mm sections with full set of compatible accessories Part of a complete ceiling system Only one type of channel for main and furring functions Increased web width for faster/easier installations and smoother joints

Where to use of those profiles:

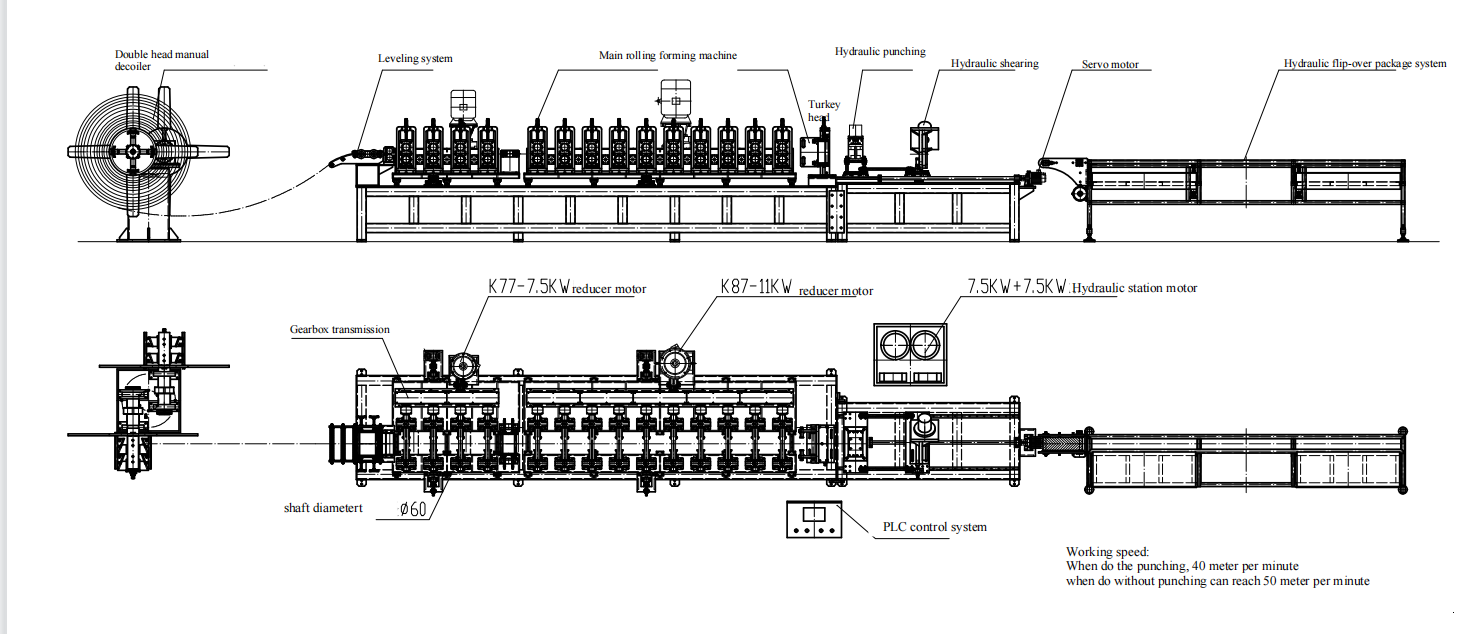

Metal profile stud rolling forming machine

Metal profile stud rolling forming machine parameters and options for your reference.

1. We have the following speed options for your reference:

Normally 25 to 35 meter per minute without punching

High speed is from 50 to 75 meter per minute with punching

Highest speed now we can reach 120 meter per minute with punching.

2. Adjustment options.

We have manual adjustment by spacer.

We have PLC control fully automatic type.

The machine working flow like this:

Light gauge steel framing omega channel angle profile light gauge steel forming machine for ceiling and drywall | ||||

| 1.Formed Material | PPGI,GI,AI | Thickness:0.5-1.2mm | ||

| 2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) | ||

| 3.Main body | Roller station | 12 rows(As your requirement) | ||

| Diameter of shaft | 50mm solid shaft | |||

| Material of rollers | 45# steel, hard chrome plated on the surface | |||

| Machine body frame | Metal steel welded | |||

| Drive | gearbox transmission | |||

| Dimension(L*W*H) | 5500*800*1200(customize) | |||

| Weight | About 3T | |||

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation | ||

| 5.Power | Motor Power | 7.5KW | ||

| Hydraulic system power | 5.5KW | |||

| 6.Voltage | 380V 50Hz 3Phase | As your requirement | ||

| 7.Control system | Electric Box | Customized(famous brand) | ||

| Language | English(Support multiple languages) | |||

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |||

| 18.Forming Speed | 60-70m/min(customized) | The speed depends on the shape of the tile and the thickness of the material. | ||

The following we share the manual adjustment machine. The advantages of it, that manual adjustment cost is more lower and if you have the engineers who are professional for machines, manual adjustment will be best options.