Maximize Your Metal Forming Efficiency with Wall Angle Rolling Machines: The Ultimate Guide

In the world of metal fabrication, efficiency and precision are critical to ensure success. Among the various tools and machines available, one stands out for its versatility and effectiveness: the Wall Angle Rolling Machine. This impressive piece of equipment has revolutionized the way professionals approach metal forming, offering countless benefits in the process. In this ultimate guide, we’ll explore the ins and outs of wall angle rolling machines, how they’ve transformed the industry, and how you can leverage their capabilities to maximize your metal forming efficiency.

What is a Wall Angle Rolling Machine?

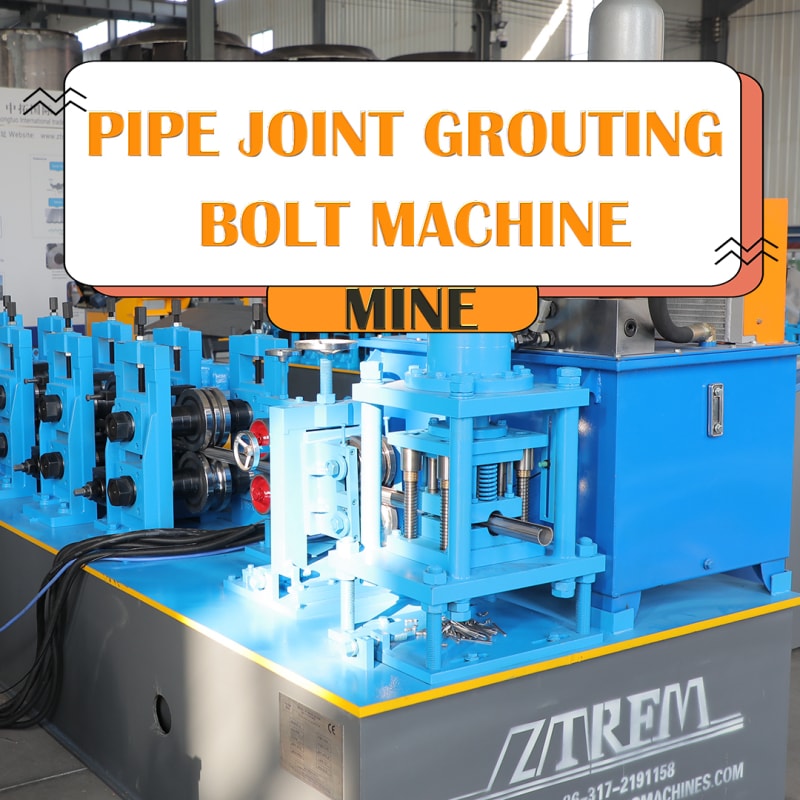

A wall angle rolling machine, also known as an angle roll bender, is a specialized metalworking machine designed to create precise bends in angle iron and other metal profiles. These machines use a series of rollers to apply pressure to the metal, gradually bending it to the desired angle. Wall angle rolling machines are widely used in various industries, including construction, automotive, aerospace, and shipbuilding, to create structural components, brackets, and frames.

Key Components and Features

Wall angle rolling machines typically consist of the following key components:

Frame: The machine’s heavy-duty frame provides stability and support for the entire operation.

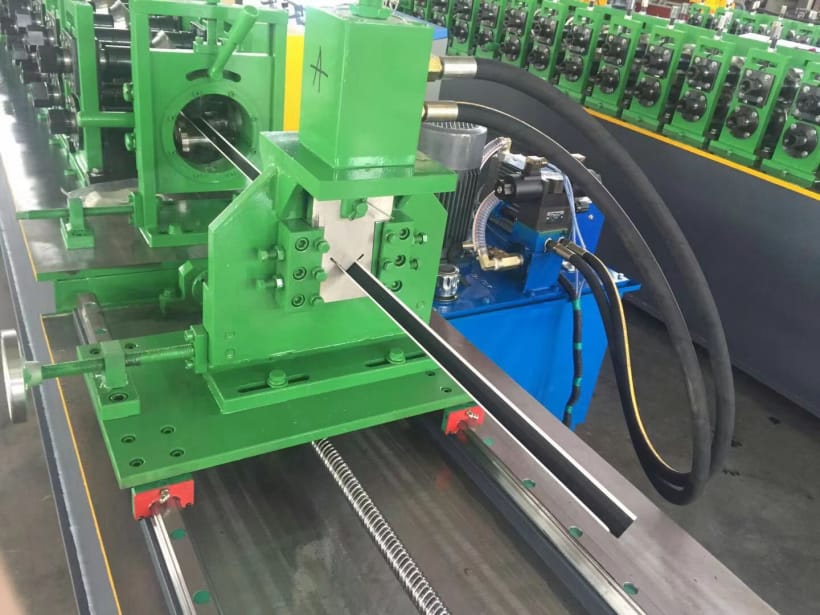

Rollers: Three or more rollers apply pressure to the metal, with one or two fixed rollers and one or more adjustable rollers to control the bend’s angle.

Drive System: A powerful motor and gearbox provide the torque needed to bend the metal.

Control System: The machine’s control system allows the operator to set the desired bend angle, monitor the process, and make adjustments as needed.

Some advanced wall angle rolling machines also feature:

Hydraulic or pneumatic systems for added power and control.

CNC (Computer Numerical Control) capabilities for precise, automated bending operations.

Touchscreen interfaces for ease of operation and programming.

Benefits of Using a Wall Angle Rolling Machine

Wall angle rolling machines offer numerous advantages over traditional metal bending methods:

Versatility: These machines can work with various metal profiles, including angle iron, flat bars, square tubes, and more.

Precision: The adjustable rollers and advanced control systems ensure that each bend is precise and accurate, reducing the need for post-processing and rework.

Efficiency: The machine’s automation capabilities and high throughput rates enable faster production times, boosting overall efficiency.

Consistency: With a wall angle rolling machine, you can achieve consistent bends across multiple pieces, ensuring a uniform final product.

Reduced Material Waste: The precise bending process minimizes material waste, resulting in cost savings and reduced environmental impact.

Selecting the Right Wall Angle Rolling Machine for Your Needs

When shopping for a wall angle rolling machine, consider the following factors:

Capacity: Choose a machine with the capacity to handle the size and thickness of the metal profiles you’ll be working with.

Control System: Look for a machine with an intuitive control system that allows for easy programming and operation.

Drive System: Consider whether a hydraulic, pneumatic, or electric drive system best suits your needs and preferences.

CNC Capabilities: If your operation requires high levels of precision and automation, consider investing in a CNC wall angle rolling machine.

Brand and Reputation: Opt for a reputable manufacturer with a proven track record in producing high-quality, reliable machines.

Maintenance and Safety Tips

To ensure the longevity and safe operation of your wall angle rolling machine, follow these maintenance and safety guidelines:

1.Regularly inspect the machine for signs of wear or damage and address any issues promptly.

2.Keep the machine clean and free of debris to ensure smooth operation.

3.Lubricate the machine’s moving parts as recommended by the manufacturer to reduce friction and prolong its lifespan.

4.Train operators on proper machine usage, safety procedures, and emergency protocols to minimize the risk of accidents and injuries.

5.Install safety guards, shields, and other protective devices to prevent contact with moving parts and reduce the risk of injury.

6.Regularly update the machine’s software (if applicable) to ensure optimal performance and compatibility with your control system.

7.Schedule routine maintenance and service visits from qualified technicians to keep your machine in top working condition.

Applications and Industry Examples

Wall angle rolling machines have a wide range of applications across various industries. Some examples include:

Construction: In the construction industry, wall angle rolling machines are used to create structural components, such as beams, columns, and trusses, as well as brackets and supports for various building elements.

Automotive: These machines are essential in the production of automotive components, including chassis, suspension systems, and body frames.

Aerospace: Wall angle rolling machines are used to create structural elements for aircraft, such as fuselage frames and wing supports.

Shipbuilding: In shipbuilding, these machines are employed to create the curved hull sections, frames, and stiffeners that give ships their structural integrity.

Furniture Manufacturing: Wall angle rolling machines are used to create metal furniture components, such as chair frames, table legs, and decorative elements.

Conclusion

Investing in a wall angle rolling machine can significantly improve your metal forming efficiency, precision, and overall productivity. By understanding the machine’s components, features, and capabilities, you can select the right equipment for your specific needs and applications. Proper maintenance, safety precautions, and operator training will ensure the machine’s longevity and safe operation. As a versatile and essential tool in various industries, wall angle rolling machines are key to staying competitive and maximizing your metalworking capabilities.