High Speed Metal Slitting Line For 4mm Thickness And 2 Meter Width

High speed and high accuracy metal slitting line for 4mm thickness and 2 meter width is designed for slitting coil in the speed of 70 to 100 meter per minute. The material could be used for stainless steel, GI steel, carbon steel and others.

A steel coil slitting line is usually referred to as a slitting line or a sheet cutting line. It is a metal-processing line where a wide sheet steel coil is slit into narrower or shorter straps. Though called a steel coil slitting line, such a processing line is sometimes used to process sheet metal coils other than steel. That said, stainless steel is the most common material a slitting line processes. The shorter or narrower steel straps will go into other metal-processing lines to produce the end products.

For making the accurate quotation, when asking the quotation, please give us the following information.

1. What is the material thickness and coil width.

2. What is the material.

3. What is the Max coil loading weight

4. How the speed and leveling & slitting accuracy you need.

After knowing those information and then we can make the accurate quotation for you.

In the following part, I will show some important elements for your reference:

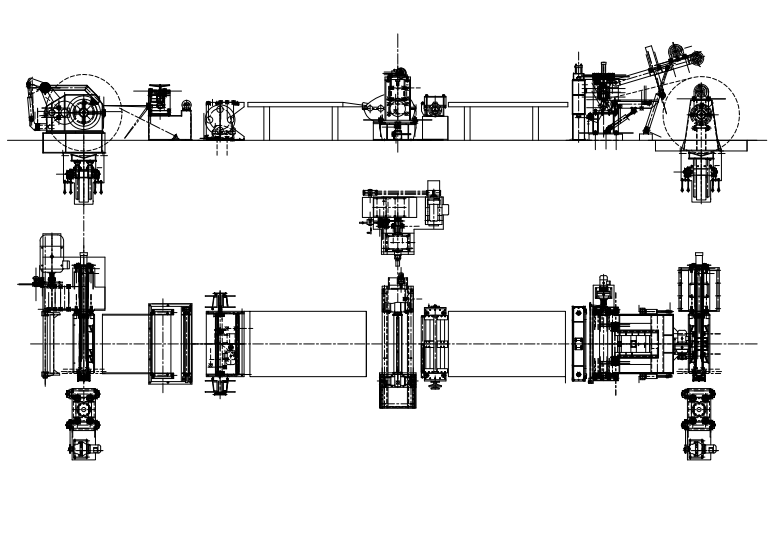

Slitting line working process:

From right to left: Entry coil loading car→Decoiler →Press and pinch device Hydraulic cutter→Looper 1→Side guide device→ Slitter Scrap winder→Looper 2→Tension stand →Recoielr→Exit coil car

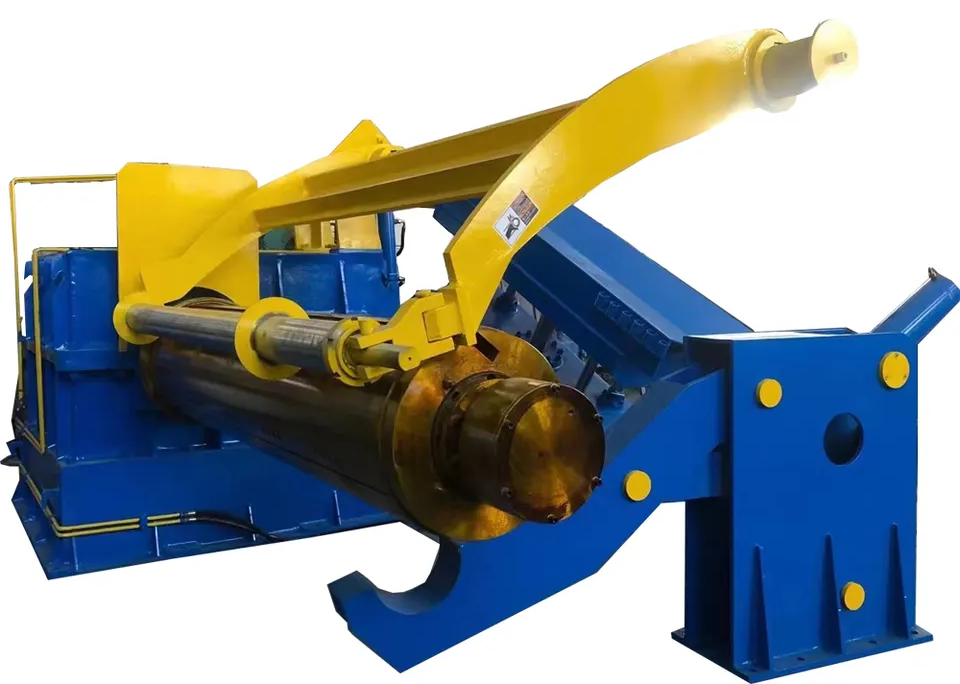

Hydraulic de-coiler

Structure:Hydraulic expand and shrink to tight the inner hole of steel coils.

Specification:Φ520max/480min×1250(width of roller)

The max capacity: 10T, with simple supporting stand.

Function: Fixed the coil to achieve unwinding function, with the brake. The car makes the inner holes of steel coils aim at the de-coiler center. The hydraulic cylinder drive the center shaft hydraulic ally to tight the inner hole of steel coil.

For example, if you need the coil to 25 ton or 30 ton, we can use the double head decoiler.

Hydraulic press and pinch device

Two hydraulic cylinders controlled unwinding rubber roller lifting.

Cycloid reducer BWY215-121 drive the running of steel coil.

Hydraulic pressing & guiding device: Driven by 11KW cycloid reducer motor. Setting manual clutch. Pinch roller pressed by hydraulic cylinders.

Drive mode using the lower roller drive. The diameter of hydraulic cylinder is: φ100

Structure: It is welding by steel plates and profiled bar

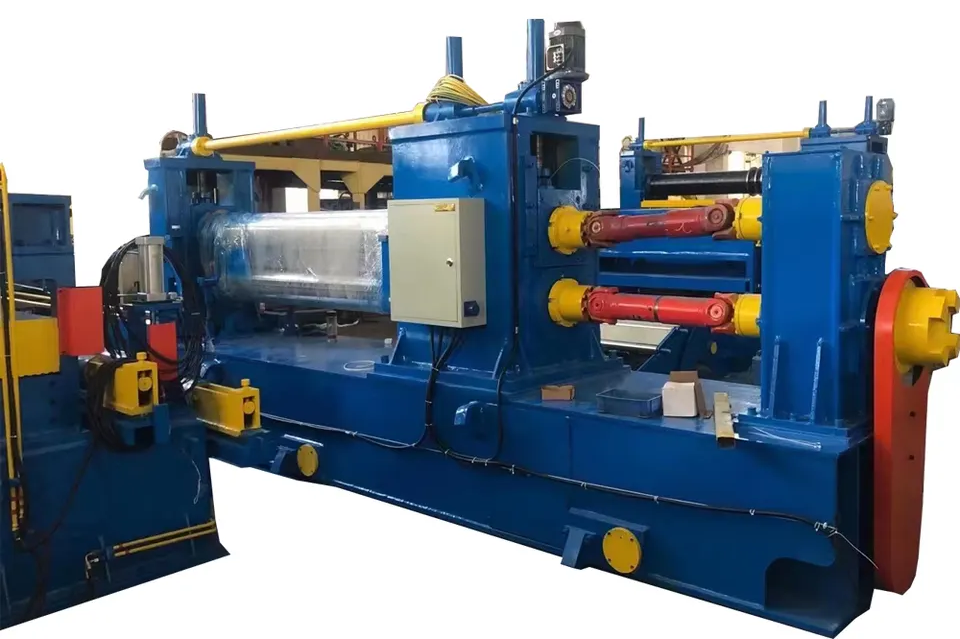

As to the slitting part:

Specification of blades:Φ360×Φ220×15 material:6CrW2Si and 10 pieces of blades and a set of spacers and rubber ring will be provided with the machine for free, Details please check the spare parts list.

Thickness of process able material:δ=4mm.

Width of process able material:B≤1250

Electric motor:Electric motor:45KW frequency conversion control motor to control the speed. Control mode is frequency control.

Reducer: cycloidal reducer

The slitting machine is designed with entry guide device, press device

Slitting speed:v≤ 40m/min.

Function: It equips the side guide device, to achieve positioning strip and stop the jumping of strip. Improve the accuracy of slitting. It can shear actively or passively. To achieve different strip thickness accuracy requirements of slitting

The last one is the recoiler: