Full Automatic Smi 1.75″ Snaplock Standing Seam Roof Standing Panel Roll Forming Machine For America

Design Idea:

Full Automatic Easy Operation:Whole producing line just need one person for operation.

Full Automatic Easy Operation:Whole producing line just need one person for operation.

Before Wave Shearing Design:For making sure the wave shape is perfect good, we design the machine with before wave shearing. As hydraulic cutting after rolling will destroy the shape.

Machine Weight | 8.2 Tons |

Machine Dimension | 7800*1200*1400 mm |

Total Power | 9 kw |

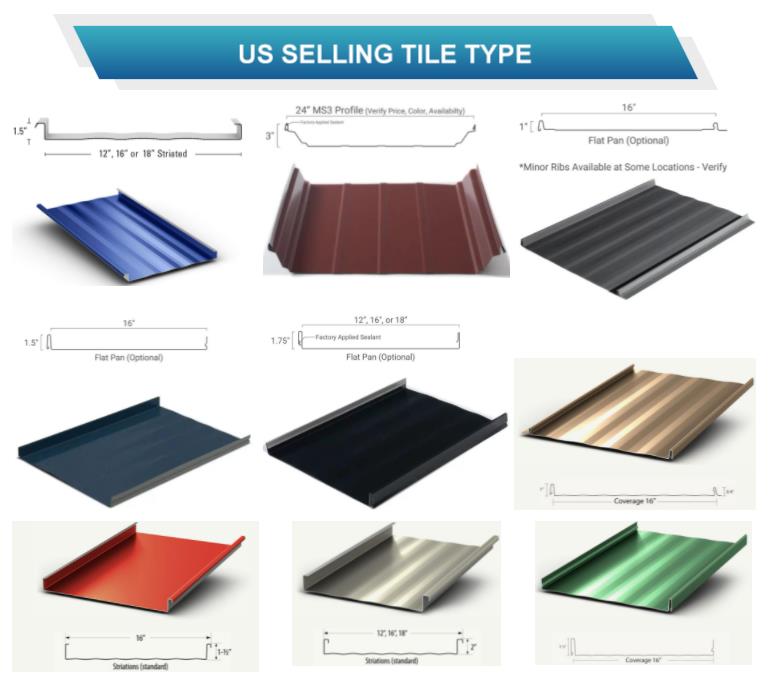

Profile drawing for reference:

this type 1.75″ SnapLock Standing Seam panel very hot sale in US.As we sold many machines to America,we have rich experience on it to confirm the finished product good and suit for market.

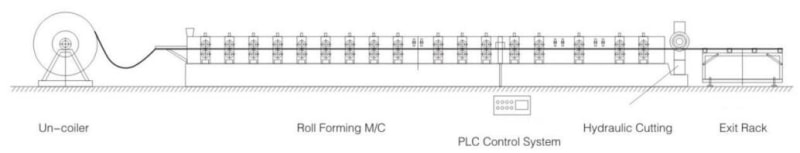

Processing Flow

Uncoiling → Feeding Material Into Machine →Roll Forming → Auto Cutting →Products Receiving

1.75″ Snaplock Standing Seam Roof Standing Panel Roll Forming Machine For America | |

Raw Material | GI&PPGI&G550 GI и PPGI и G550 |

Material thickness:22-24 gauge (0.3-0.8 mm) Coil width :545 to 600mm Effective width:430 mm | |

Machine Frame | 350# H steel welded,Steel plate welded structure |

Material Of Rollers | 45# Steel,Chromed treatment, improve the hardness and prevent abrasion, anti corrosion increase of service life |

Rolling station | Roller stations :16 rows |

Diameter of shafts | Φ75mm solid |

Material of shafts | 45# STEEL,Tempering treatment to prevent deformed and improve hardness |

Forming speed | 20 m/min |

Voltage | 380V/50HZ/3P (as requested) |

Transmission way | By Chains with cover |

Main motor | 5.5 KW |

PRODUCT DISPLAY