Corrugated metal sheet is a very widely used sheet product. It can not only be used for industrial or residential roofing, but also can be used as fences. Due to its very large demand, there are more and more manufacturers to produce corrugated roofing sheet.

However, due to the differences in regions, the scales of manufacturers are different, and the needs of different corrugated roofing sheet manufacturers are also different. Therefore, based on the standard version of the machine, we designed and developed an enhanced version of corrugated roofing sheet machine.

Here we use a commonly used corrugated roofing sheet to show you.

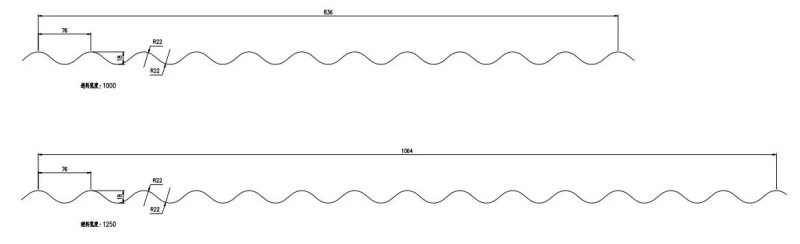

This is the drawing of one popular corrugated roofing sheet.

Material: PPGI GI PPGL GL Al

Thickness: 0.3-0.8mm (For materials with thickness less than 0.2mm, a barrel corrugated forming machine can be used)

Finished corrugated roofing sheet

Features of enhanced corrugated roofing sheet machine

Advantage: Higher production speeds, larger machine frame and stronger construction than economic type

It is suitable for customers who have higher requirements for machine quality.

Feature

Machine frame: 400H steel (500H steel optional)

Structure: cast iron archway, more durable and stronger

Control system: PLC, support multi order input (for different length and quantity)

Drive: by chain (with protect cover) or

By gearbox (High transmission efficiency, high precision and fast speed than chain, but price is higher)

Cutting method: hydraulic cutting system(Stop shear, when the shearing action is performed, the forming process will stop temporarily.)

Production speed: 0-20 meter per minute

Decoiler: manual decoiler (hydraulic decoiler optional)

Stacker: simple run out table

Need workers: 2-3 person

Power: 9-12KW

Machine picture for reference.

For more information of corrugated roofing sheet machine, please contact with us. We can customize the machine with professional solutions according to your needs.