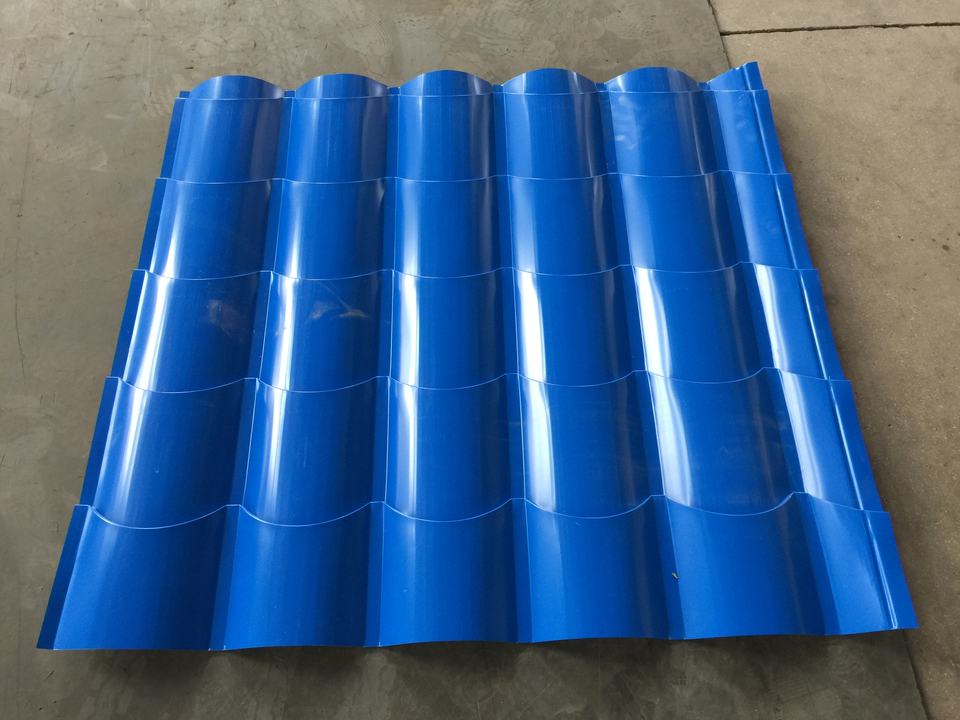

Zinc roofing tile roofing sheet roof panel making rolling forming machine

Design Idea:

High speed:2-4m/min

Stable Transmission: chain drive

Processing Flow

Decoiler-Feeding Material-Roll Forming-Cutting-Receiving The Product

Metal Glazed Roof Tile Roll Forming Machine Hot Sale To Azerbaijan | |

Raw Material | PPGI |

Material Thickness: 0.32-0.8 Mm | |

Machine Frame | 350# H Steel Frame Welded |

Machine Structure | Vertical Arch Frame Structure |

Material Of Rollers | 45# Steel,Chromed Treatment (Cr Thickness:0.05 Mm), Anti-Corrosion,Increase Hardness, Ensure The Precision And Good Abrasion Performance. |

Forming stations | 16 stations |

Diameter of shafts | Φ70mm |

Material of shafts | 45# Steel Tampering Treatment, Prevent Deformed And Improve The Hardness |

Forming speed | About 2-4m/min |

Voltage | 380v 50hz 3phase Or As Request |

Transmission | Gear Box Transmission(Bevel Gear Inside) |

Material Of Gear: 20 Crmnti | |

Material Of Gear Box: 20mm steel wall plate | |

The connection between gear boxes are chains | |

Gear box will connect with the rolling station one for one | |

Advantage: can improve the speed directly after cutting | |

power supply | 5.5kw for the main motor power |

Cutting blade material | Cr12Mov quenched treatment to improve hardness |

Cutting type | Hydraulic cutting |

PRODUCT DISPLAY

5Tons manual decoiler Type: Manual Carrying capacity: 5t Uncoil : 1220 mm Inner diameter: 450-550 mm Quantity: 1 set | |

Feeding Device 1. Rubber rollers protect raw material surface 2. With handwheels easy adjust for feeding different thickness raw material. 3.the platform width is adjustable by hand wheel, have the bearing inside to protect the edge of the steel sheet. | |

Roll Forming Device 1.45# Steel,Chromed Treatment (Cr Thickness:0.05 Mm), Anti-Corrosion,Increase Hardness, Ensure The Precision And Good Abrasion Performance. 2. Each roller has number and with keynotes, it can fix on the shaft stablely | |

Transmission Device Gearbox transmission,stable and no loose. | |

Hydraulic Cutting Device 1.Adopt double oil cylinder more stable than single oil cylinder 2.Hydraulic motor power 5.5 kw with energy accumulator 3.Cutter material :GB-Cr12 with heat treatment 4.Cutting length tolerance ±10m/2mm 5.Cutting feature :Steady and safe working condition and low sounds | |

PLC control system Brand PLC brand : Delta Inverter brand: Delta Low electric part: Schneider Encoder: Omron Function: 1.Adopted aviation plugs,easy installation. 2.Full automatic easy operation. 3.Operation language:English(provide customized) 4.National coinsurance,spar parts Brand Siemens and Schneider. | |

Hydraulic station 4.5kw motor with cooling system for long time using. | |

Automatic Stacker Stacking principle: the top sheet will not damage the sheet below, the profile of the sheet below will match the profile of the top sheet Max. Length of the sheet: 3000 mm Max. Width of the sheet: 1250 mm The thickness of stack: 300 mm Carry arms control: pneumatic (the air pump is provided by the user) Push system: cylinder driving and controlled by control station, function: to align the sheets |