GI GL PPGI PPGL full automatic metal coils slit and cut to length machine:

1600×3.0mm leveling and slitting and cut to length machine with 15 tons hydraulic decoiler and loading cart

MACHINE PHOTOS FOR YOU REFERENCE:

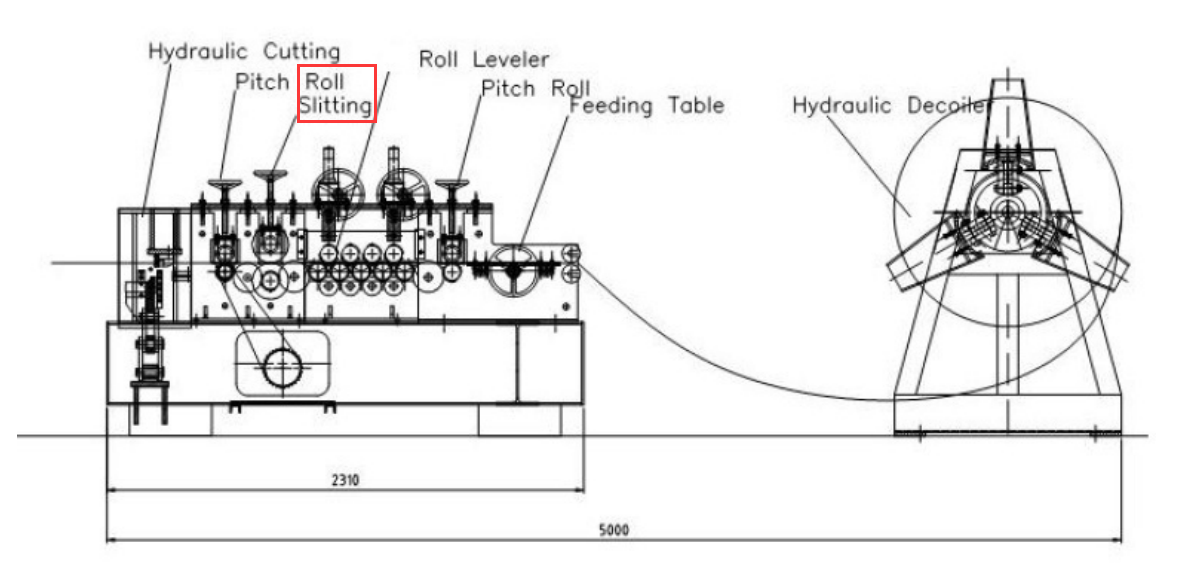

PROCESS AND COMPONENTS:

- 15tons hydraulic decoiler with loading cart : 1 set

- Leveling and slittingmachine : 1 set

- Hydraulic shearing system : 1 set

- Hydraulic station : 2 sets

- PLC Control system : 1 set

WORKING FLOW DRAWING FOR YOU REFERENCE:

Main parameters for you reference:

- Input : 1600mm

- Thickness : 5-3.0mm

- Rollers : 6 up 7 down, 2 input

- Shaft : Φ110mm

- Wall panel : 25mm, A3 400H steel frame

- Drive motor Power : 15kw

- Speed : 0-15m/minute

- Hydraulic power: 7.5 kw

- Driven : gear box

- Slitting and shearing blade: Cr12

- Slitting quantity : 6 strips maximum

- (The slitting blades can be lift up and down and at the same time the blade width is adjustable)

- The machine can leveling and thenslit and cut to length.

- Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase (this is can depend on customer request)

Our machine photos for you reference:

ADVANTAGES OF OUR MACHINE:

1.Our machine with 15t loading capacity decoiler, and our decoiler have more functions: such as the loading cart, pneumatic brake, hydraulic press arm (this is necessary expecially for the 3.0mm thickness coils. And our decoiler have the hydraulic support holder, this can let the decoiler working more stable. Here I attached photos with you.

2.Our machine adopt gear box transmission type, this is more stable and at the same time life time is longer. If the machine adopt chain transmission then after used a period of time the chain will loose and customer have to change the new chain, and if the chain is loose then the machine can not guarantee the cutting precision.

3.Our machine adopt both top and bottom rollers active leveling, this is more better for the leveling precision.

4.There are reducer wheels on the top of our machine, this can let the adjust of the roller gap much easier when you process different thickness sheet.

5.The guide rollers can guarantee the slitting precision. And much easy for adjustment at the same time not hurt material.