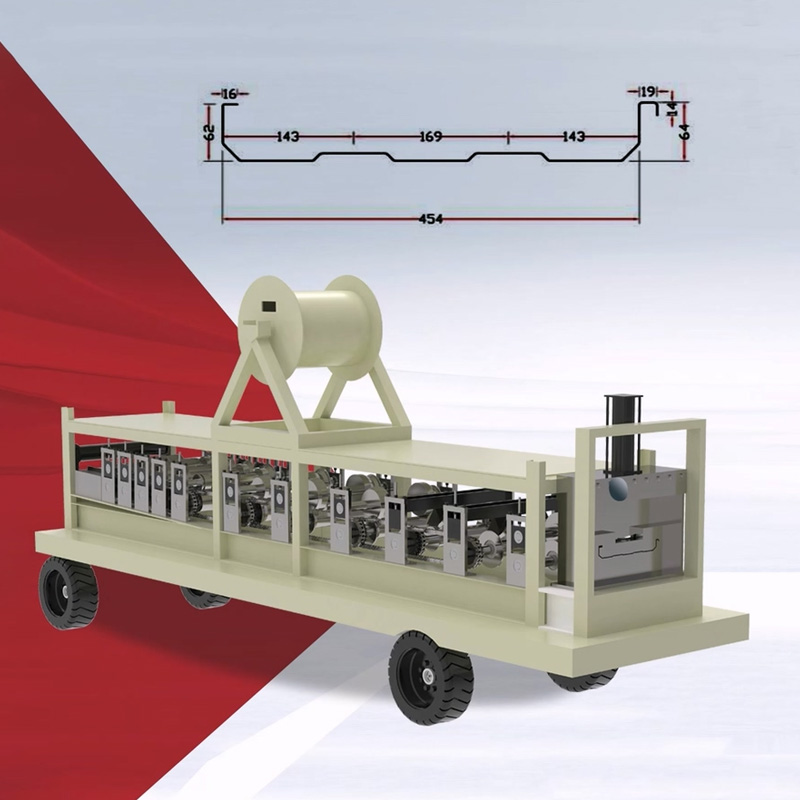

Aluminum magnesium manganese roof panels are a type of flat roof material that is commonly used on roofs and walls in many buildings today. Due to the characteristics of aluminum magnesium manganese roof panels in the field of characteristics, the application market prospects in today’s construction industry are quite promising. Today, let’s learn about the advantages of low rise aluminum magnesium manganese roof panels.

Aluminum magnesium manganese roof panels have brought great benefits to contemporary architecture, such as comfort, lightweight, durability, economic development, and environmental protection. Therefore, when using aluminum magnesium manganese roof panels, we also need to understand the advantages that arise. Aluminum magnesium manganese roof panels have moderate structural strength, especially resistance to dirt, and are easy to bend sheet metal, In the application process, aluminum magnesium manganese roof panels can fully utilize their excellent operational characteristics.

It is important to understand this challenge. Currently, aluminum magnesium manganese roof panels have been used for over 50 years in flat roofs or wall materials, making them a highly utilized material at the building level. This is closely related to their lifespan, as the longer the application time, the lower the maintenance and upkeep costs, Moreover, the total weight of aluminum magnesium manganese roof panels is also very light, and they have strong corrosion resistance when applied.

The surface solution is also very diverse, and they can achieve different advantages such as beauty and elegance in the application process. It is also because aluminum magnesium manganese roof panels have this advantage that they have been more widely used and have good conductivity.

1. In terms of durability, aluminum magnesium manganese roof panels form an air oxide layer through chemical reactions with air to maintain the effectiveness of the material. Color steel plates are relatively prone to corrosion, especially in some unfavorable weather conditions, and their welded parts are particularly prone to corrosion.

In terms of net weight, aluminum magnesium manganese roof panels have a net weight of about one-third of that of color steel plates, making them more convenient for construction and transportation.

3. Its raw materials often contain magnesium and manganese, thus possessing a certain strength, and the strength of color steel plates is also relatively good. This is difficult to distinguish.

4. It can use various industrial production techniques to make its appearance more beautiful, while color steel plates can only be compared from a reliable perspective after painting. Its melting point is high, while color steel plates have a low melting point.

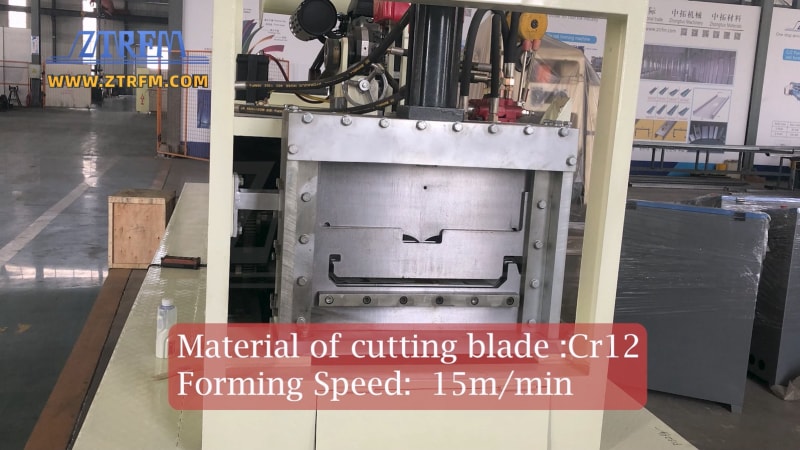

(1) Company Introduction: Cangzhou Zhongtuo comes from Hebei Province, China and is a manufacturer dedicated to designing and manufacturing different types of cold bending forming machines. We are a factory with a long history, engaged in the design and manufacturing of cold bending forming machines since 2006. The machines we can produce include: roof tile machine, CZ steel machine, light steel keel machine, metal embossing machine, door forming machine, ceiling system forming machine, high-frequency welding pipe machine, longitudinal cutting line, transverse cutting line, shelf system forming machine, floor support plate machine, color stone tile production line, etc.

(2) Enterprise Technology and Qualification: The company has its own product research and development room, testing room, laboratory, etc., and has passed 22 various patents. It is a national high-tech enterprise, a provincial-level specialized and innovative enterprise in Hebei Province, a technology innovation oriented enterprise, a demonstration enterprise in the cross-border e-commerce industry in Hebei Province, and a master’s internship base at Yanshan University. Zhongtuo Company collaborates with an external expert team to cultivate technical backbone internally, and continuously iterates products based on international trends and market demands.

(3) Customer recognition: The company instills the concept of quality as life into the hearts of every employee. Control equipment quality while improving production efficiency and shortening delivery time. All equipment must be tested before shipment and any problematic equipment will not be delivered to customers. We have rich export experience and understand the different needs of customers in developing and developed countries. Over the years, we have provided many satisfactory equipment solutions for our customers. Nowadays, our equipment has been exported to more than 150 countries around the world, and we have established long-term and stable cooperative relationships with customers, gaining their unanimous support