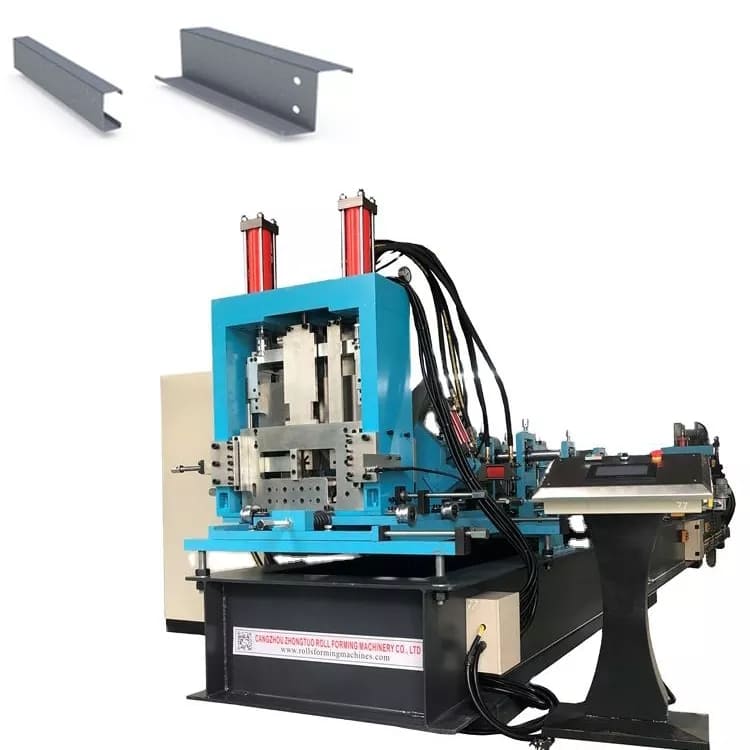

The CZ purlin machines are specifically used to manufacture multi-size C and Z purlin channels, We manufacture Automatic and Semiautomatic type CZ interchangeable Purlin Machines in US.

The first one is an Automatic Interchangeable CZ machine with the advantage of Easy to operate PLC based system used to change between C and Z purlin in an instant without any hustle.

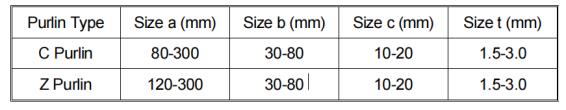

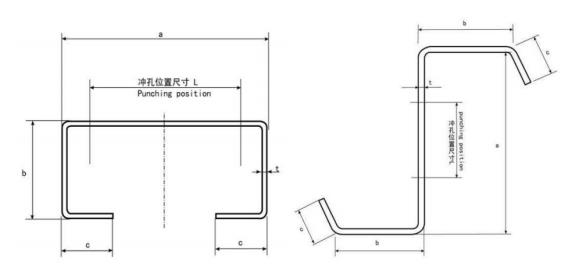

The C and Z purlin produced by this machines are of high quality and scratchless material, and is best suited for sized from 80-300mm and on.

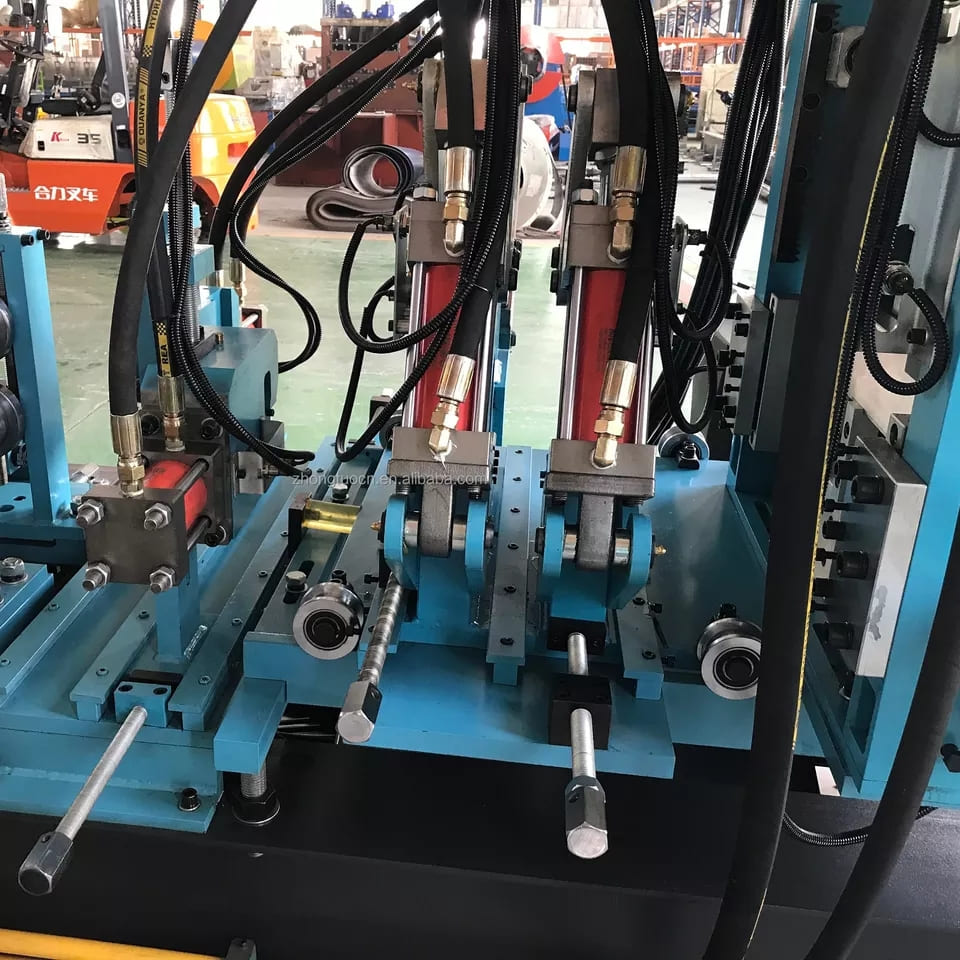

The Machine’s parts are all made with precision and experienced personals, with optimum quality roll tools so you never have to worry about the quality.

The Roll tools are carved in highly precise CNC machines which gives it the best quality and long life as we say “Quality & Service are the main ingredients of our Machines”

This kind of C Z Purlin Machine are made with highly durable and strong Structures, which are used to made high quality Door Frame, Pallet Rack, Pack Post, Swage Beam Panel and Glass Wool Panel Profiles based on the customized Shapes.

Motorized Rolling Shutter: The main feature of our motorized rolling shutters is its robust structure obtained due to the use of high strength metals in the making of slate and guide profile. These shutters require low maintenance enabling very less inspection & manual attention, and our motorized rolling shutters have very easy operation ensuring total customer satisfaction.

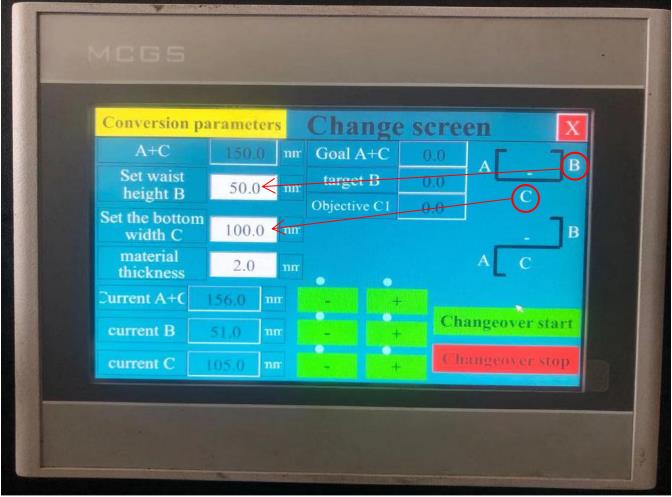

How to adjust the sizes by PLC operation? Expect PLC setting what other work we should do?

Input the height and bottom width of the product you want to change and the thickness of the material used in the white background input box on the screen, click changeover start, and the size adjustment motor starts to automatically adjust the roll forming parts to the required position.

Then you need to manually adjust the hand wheels on both sides of the feed inlet and vertical guide wheel between leveling and punching unit to adapt to the adjusted feed width.

Then start the machine, feeding and roll forming. When the material is close to the cutter, stop the machine, observe the position of the product and cutter gap from the front of the machine, and adjust the cutter by adjusting the bolts on the top of the cutting device (adjusting the cutter height), on the left side (adjusting the cutter width), and on the right side (adjusting the overall position of the cutter), so that the formed material can be aligned through the gap.

Contact information:

Whatsapp: 0086 18631755623

Email: cnzt011@zhongtuocn.com