Corrugated metal roofing is a metal sheet that is roll formed into a metal panels. The traditional shape of corrugated sheet metal is round and wavy. It is low cost, light weight, durable, energy efficient, long lasting, and easy to install. Corrugated metal roofing is an excellent alternative to asphalt shingles or clay tile roofs. The durability of corrugated panels makes them a fit for both commercial and residential applications when used for metal roofing and metal siding projects. They are even used in other areas of the home including the ceiling, wainscoting and as fencing.

Zhongtuo corrugated roofing roll forming machine is designed according to Peruvian market demand and Peruvian customers’ requirements on steel coil specification, voltage, profile size, etc. to meet Peruvian market demand.

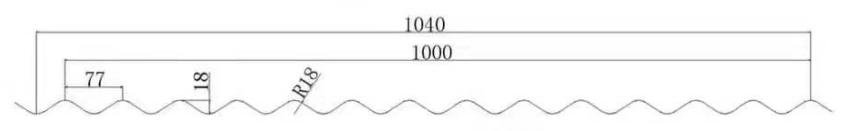

Profile drawing as follow

Suitable material: PPGI GI

Material thickness:0.3-0.8mm

Coil width: 1220mm

Finished corrugated roofing

Feature of corrugated roofing sheet roll forming machine

The stainless steel rollers with built-in bearing, several groups of nylon wheels installed on the feeding platform and the nylon gasket in the guide groove can smoothly feed the steel coil to the roll forming machine, effectively avoiding scratches on the coil paint surface.

With manual cutter, avoid waste of coil. When you complete the quantity you need, you can cut the coil from the feeding inlet.

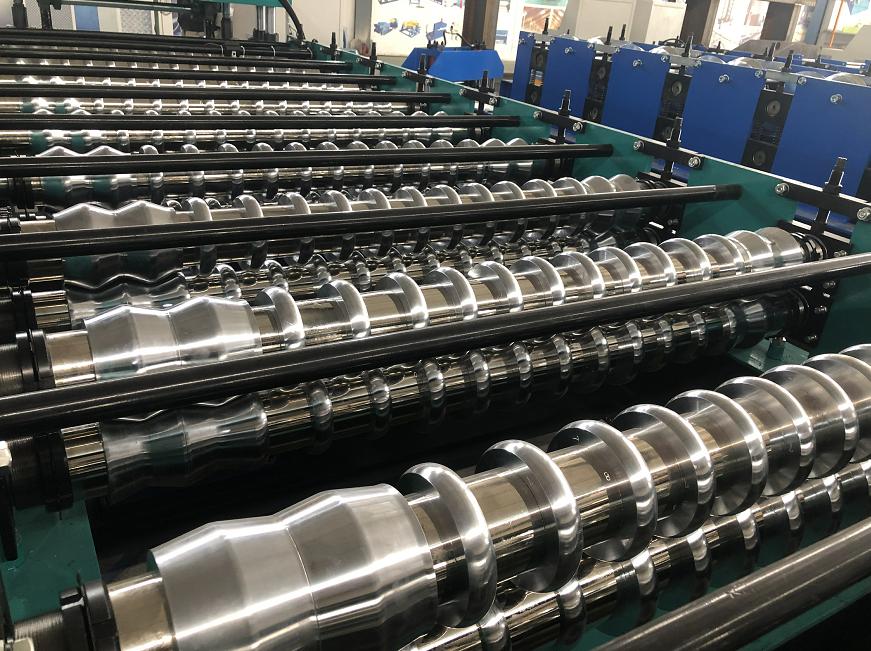

Rolling Shaft: 75mm solid 45# steel, tempering treatment to prevent deformed and improve hardness.

Rollers: 45# steel, Hard chromed coated, improve the hardness and prevent abrasion, anti corrosion increase of service life.

Production speed:0-20m/min

Voltage: 380V-60HZ-3P or 220V-60HZ-3P

PLC control system: Delta

Inverter: Delta

Encoder: Omron

Low voltage electric part:Schneider brand

Double pillar structure hydraulic shearing system

Cutting blade material: Cr12MoV

The balance shaft makes the force on all parts of the cutter more uniform, ensuring perfect shearing effect and prolonging the service life of the cutter.

Advantage of corrugated roofing sheet roll forming machine.

- Easy to installation, simple operation, low failure rate

- The design of the feeding inletand the forming mold can effectively avoid the scratch of the coils paint surface, ensure the perfect forming effect, and make the finished corrugated roofing use longer.

- Lifelong technical support eliminates your worriesduring operation.