Color Steel Metal Roofing Tile Making Machine is the machine to produce the metal tile which is used in roof,this is very popular model which is very famous in the whole world.

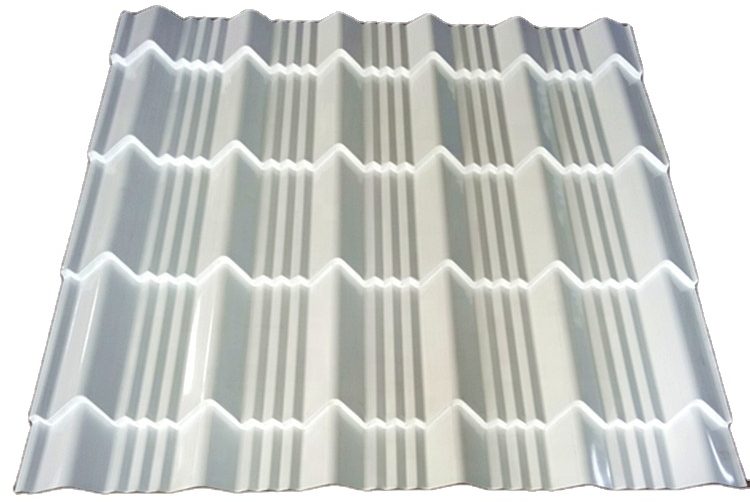

The other designs of the metal roofing tiles:

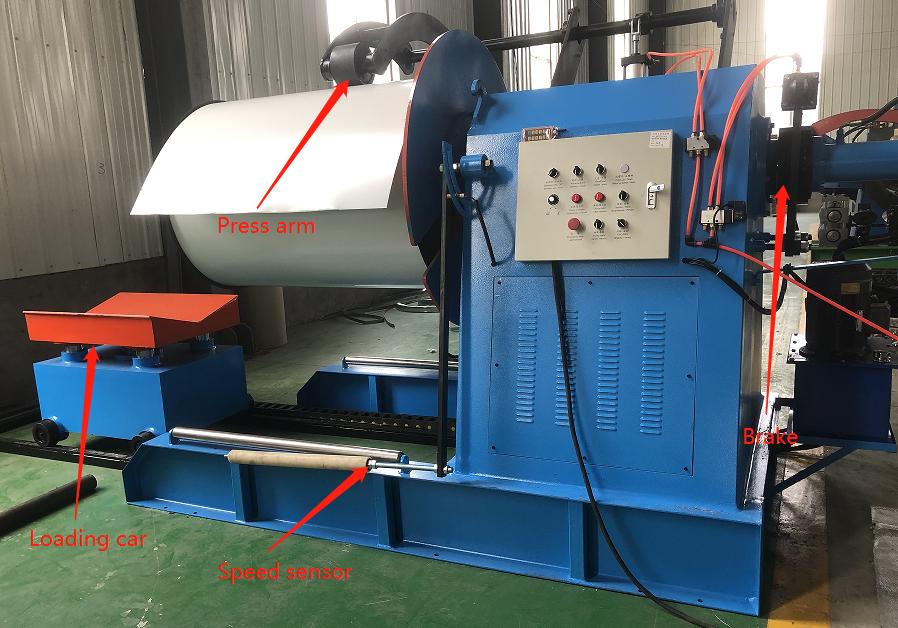

The roll forming machine to produce the Metal roofing tiles:

The technical specifications of the Color Steel Metal Roofing Tile Making Machine:

Key Features of Zhongtuo’s Color Steel Metal Roofing Tile Making Machine:

- Precision Roll Forming:

- The machine utilizes an advanced roll forming process, ensuring that the color steel roofing tiles are produced with high precision in terms of dimensions, thickness, and profile accuracy. This guarantees consistent quality across large production volumes.

- Customizable Profiles:

- Zhongtuo offers flexibility in terms of tile profiles. Whether you need classic or modern tile designs, the machine can be configured to create different styles of roofing tiles, such as Spanish, trapezoidal, or traditional wave patterns.

- High Production Speed:

- The machine is designed for continuous, high-speed production, allowing manufacturers to meet large-scale demands efficiently. With automated feeding, forming, and cutting, production lines can run smoothly with minimal manual intervention.

- Material Versatility:

- This machine is designed to process various types of materials, including pre-painted galvanized steel, aluminum, and other coated steel sheets. It can handle different thicknesses and widths depending on the project requirements.

- Automation and Control Systems:

- The machine is equipped with a PLC (Programmable Logic Controller), allowing for automated control over the entire production process. Operators can easily adjust parameters like tile length, width, and cutting intervals through the control panel. This system ensures that each tile is produced with consistent quality and precision.

- Hydraulic Cutting System:

- The integrated hydraulic cutting system allows for precise, clean cuts at the desired length without deforming the tiles. This feature enhances the efficiency of the production process and ensures high-quality finished products.

- Durable Construction:

- Built with high-strength materials, Zhongtuo’s machines are known for their durability and long service life. The robust frame and components reduce the need for frequent maintenance and repairs, minimizing downtime and operational costs.

- Optional Accessories:

- The machine can be equipped with additional features, such as automatic stacking systems, decoilers, and sheet leveling devices, further improving productivity and ease of operation.