C8 and C25 metal roofing sheet machine for Russian

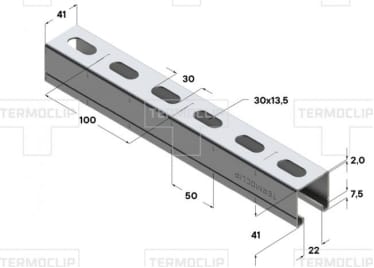

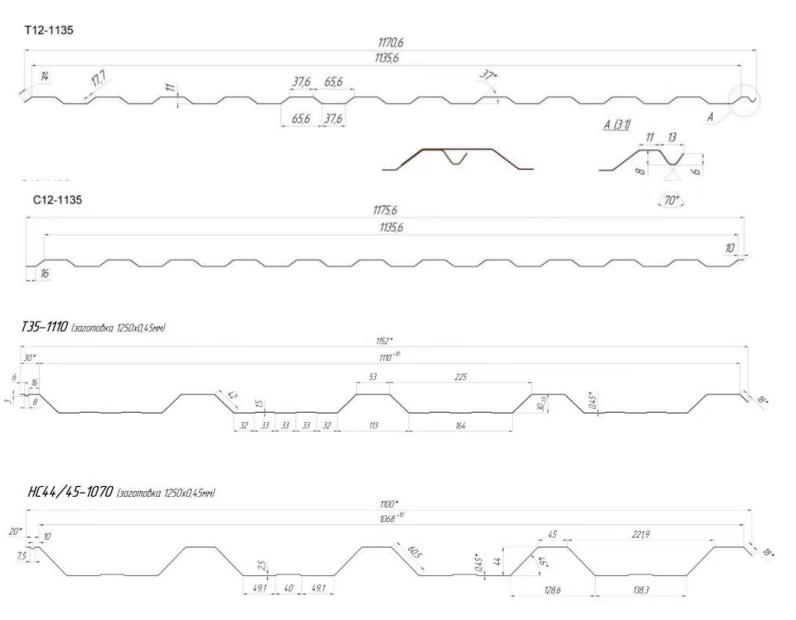

C8 and C25 metal roofing sheet machine for Russian is designed to make the metal roofing sheet in batch fully automatically. Those profiles like C8, C25, C35, C44 and others, and they are also called as T8, T25, T35, T44 metal roofing sheets. Those profiles are mainly for European and Russian market for wall cladding and roofing. And those profiles, we can either design them as single layer or double layer. The power of shearing we can design it as hydraulic shearing and motor shearing. Here are some drawing profiles for your reference:

As to the machine designs, we have the following options for your reference:

Option A: Single layer roofing sheet machine

Option B: Double layer roofing sheet machine

Option C: Shearing could be hydraulic or motor shearing.

Compare: When shall we choose single layer or when better by double layer.

- Single layer can do the production fast but double layer works only one layer each time.

- Double layer takes up small space and save some cost compared with two sets single layer machine.

- Single layer is easy to do the installation and maintenance.

Compare: When shall choose hydraulic shearing and when better by motor shearing.

- Shearing by hydraulic more power for thin sheet better.

- Motor shearing can reach higher speed.

- Hydraulic shearing saves more electricity.

- When super hot and super cold, hydraulic shearing is not so powerful like motor shearing.

- Motor shearing will be not effected by the temperature.

Optional elements: Hydraulic before shearing.

It allows you to use it at the cut to length machine. PLC control, it can help to cut at specified length.

Main motor, you can choose to use normal motor, but if you need to reach higher speed, you can choose to use the servo motor.

As to the stacker: it can help you save more workers and enhance the machine working speed: And also we can add rail at the stacker or decoiler and then many machine can use this same stacker and decoiler.

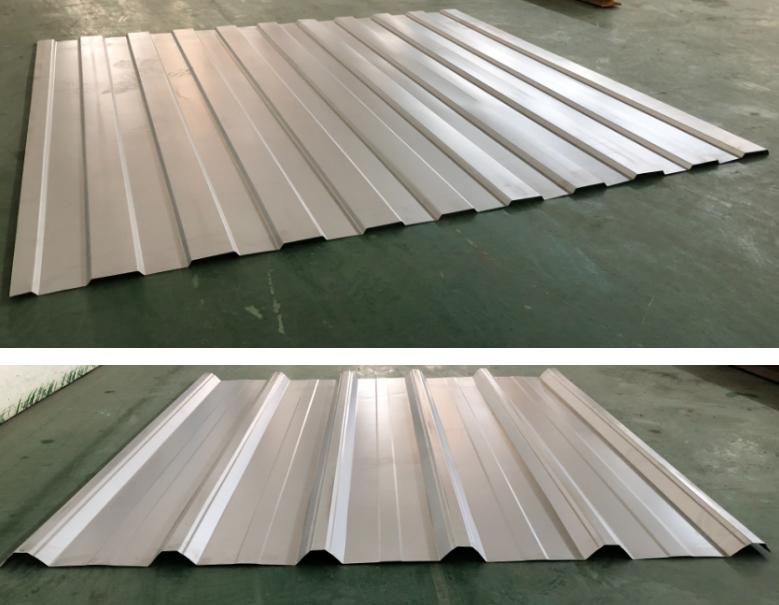

Here are some finished product pictures for your reference: