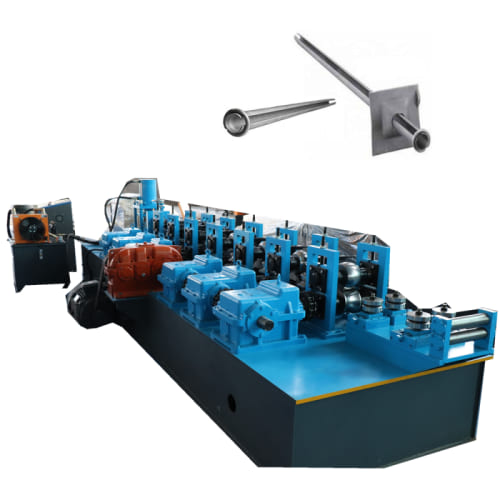

Cold Saw for 2” Tube Mill

EquipmentSpecification General typeand picture: ZT-28 Scopeof application: Carbon steel, Q235 and Pipespecification: Round: MAXØ50 mm Square:MAX35X35mm Rectangle: less than MAX20X50mm Wall thickness: 0.6 ~ 2.5mm Inside bead NOT removing. line speed: 120 m/min.(Less than 25 in diameter) Cuttinglength: 5 ~ 99 meters. Lengthprecision: ±1.5 mm (line speed fluctuating less than 2%) ElectricDescription Drivingmotor: servo motor 11KW/2000rpm, from PHASE, Servo controller power: 11KW, from PHASE Feeding motor: servo motor1.9KW/2000rpm, from PHASE .Servo controller power: 2KW from PHASE Blademotor: AC motor 5KW/1460rpm, from SIEMENS. Frequency converter power: 11KW SIEMENS Servo controller power:11KW ,SIEMENS Allthree motor cable from Germany SIEMENS Lengthmeasurement:2000 pulse IP65 waterproof and dustproof from OMRON.…