3.0x1250mm metal slitting line with 8t loading capacity decoiler and recoiler: this is a widly used slitting line, this machine can slit the coils thickness from 0.5mm to 3.0mm, because most of the customer they slit the coils thickness within 3.0mm, so this machine can satify most of the customer’s demand. And at the same time, this machine have the 8t automatic decoiler and recoiler, both of them have the loading cart, this can improve the working efficiency, and save the labor cost.

There are some advanages of this slitting line:

- This machine can slit the metel thickness from 0.5mmto 3.0mm.

- This machine speed within 30m per minute, this speed do not need the pits, this can save cost for customer.

- This machine the price is cheaper compared with the high speed professional machine.

Here below is our machine main parameters for you reference:

|

Steel coil parameters | Material | Cold rolls OR hot rolls |

| Tensile strength | δb≤450Mpa,δS≤260Mpa | |

| Steel thickness | 0.3-3.0mm | |

| Steel width | 800-1250(Max) | |

| Steel coil I.D | Φ508mm | |

| Steel coil O.D | φ1600mm(Max) | |

| Steel coil weight | 8T(Max) | |

| Slitter parameters | knife pivot diameter | Ф180 mm |

| Knife pivot material | 40Cr | |

| Blades specification | Φ180mmXφ360mmX20mm | |

| Blade material | 6CrW2Si | |

| Slit parameter | Slit quantity | 5-6 strips with 4-5 blades |

| Minimum slit width | 50 mm (3.0mm thickness) – 40 mm (0.3mm thickness) | |

| Width precision | ≤±0.05 mm/2M | |

|

| Whole line Dimension | 25 m (L) X 8 m (W) |

| Speed | 25 m /minute | |

| Operator needed | 1 mechanical engineer 2 common workers | |

| Line direction | From right to left (Face to machine) | |

| Machine color | White gray |

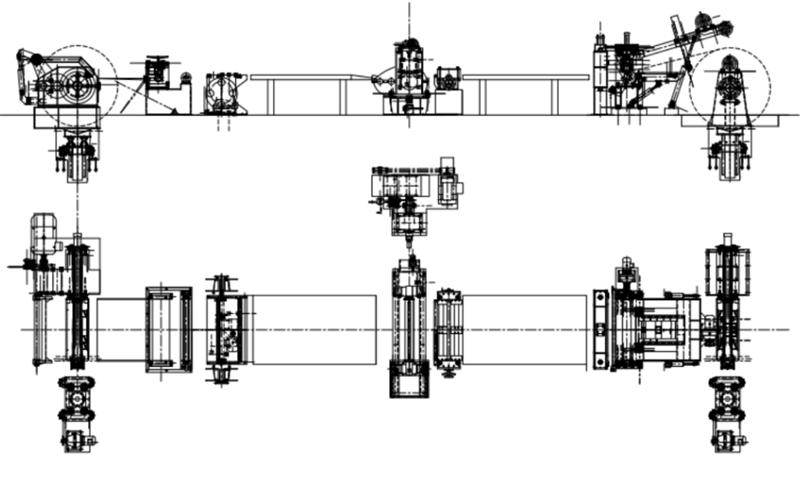

Here below is our machine working flow for you check:

From left to right are: Entry coil car→Decoiler →Press and pinch device→Hydraulic cutter→Looper 1 →Side guide device→ Slitter→Scrap winder →Looper 2→Tension stand →Recoiler→Exit coil car.